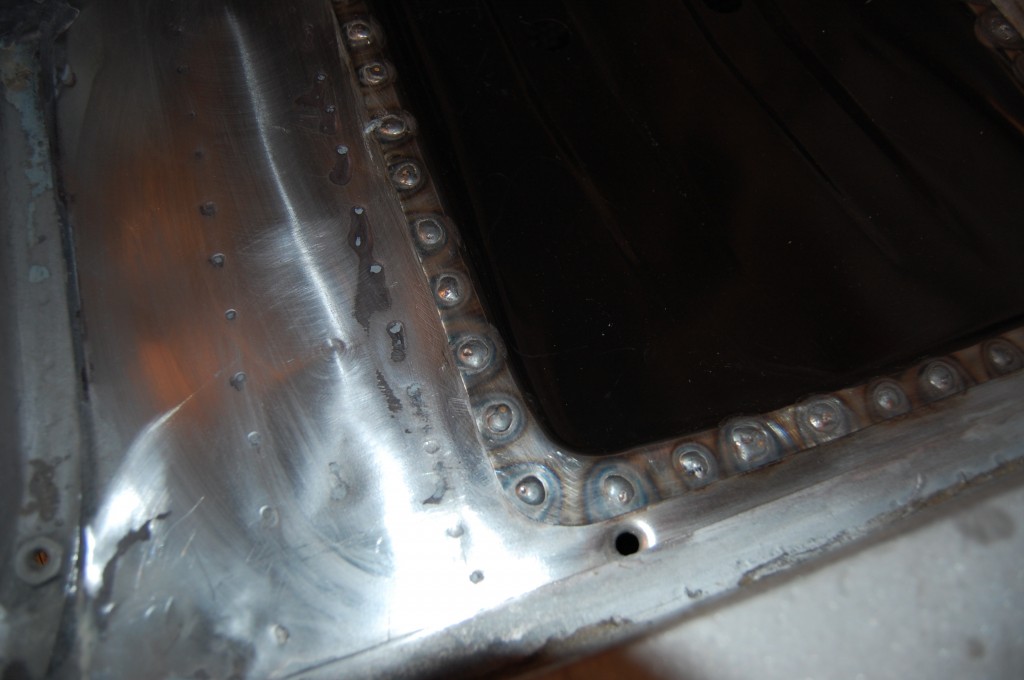

Here is a shot of the solid, but damaged footwells. Even on a bench, this is alot of damage that has alot of stretch on a complicated shape. Installed on the car, it is virtually impossible to reshape this, so these will be replaced.

The floors on this car are ROCK solid, but the footwells have suffered heavily over the years from various bashing from underneath, and rough hammering back out from above. Since the sides of the footwells show prominently on a finished car, and the footwells are not accessible with a planishing hammer or hammer and dolly, we elected to replace these with new panels.

Footwells are one of the few panels we do not make in our fabrication shop – they need to be pressed, and are readily available from several sources. These footwells are from an American supplier, and are very good reproductions, with a high-quality primer that we have elected not to strip.

The painstaking removal of the original footwell is complete - great care has been taken to avoid any damage to the floor panel itself.

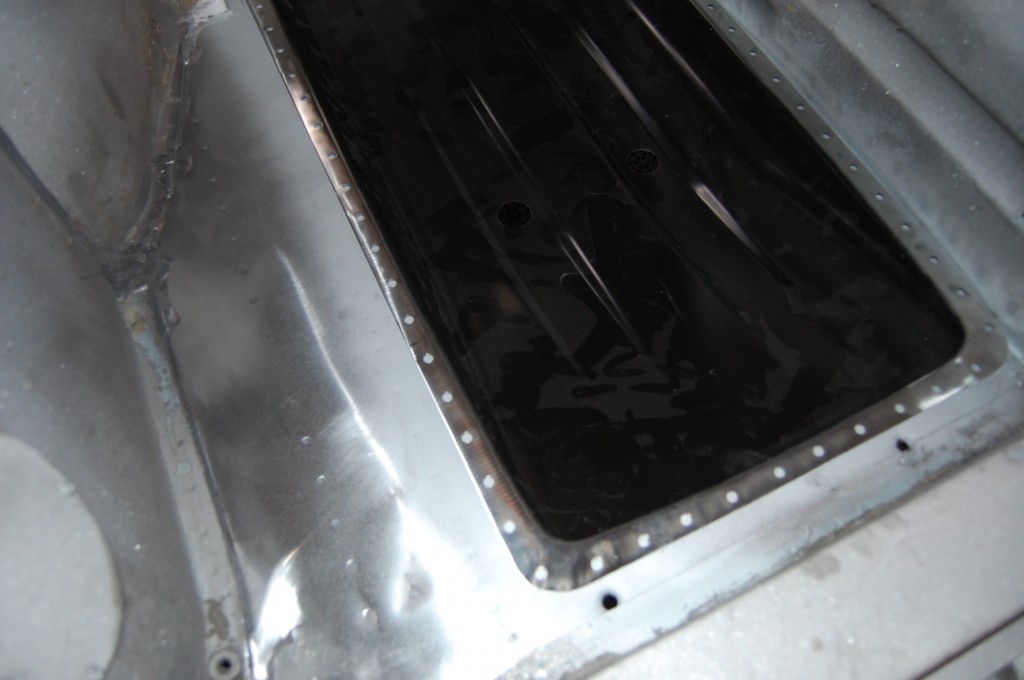

The floor panel has been cleaned and straightened, and the new footwell has been dressed and prepared for plug-welding.

Like everything else on E-Types, these footwells were originally spot-welded. However, that’s not an option here because I can’t reach up in there even with my largest tongs… I also do not like/recommend spot welding new panels to old ones – you get alot of “blown out” spot welds in that case and it makes a big mess. That would have been the case here especially, since it was tough to get the flanges flat… I have another model of spot welder that works from one side, but it is not recommended for structural welds and these need to be strong or they will pop over time as the car flexes…

What we did here is called “plug welding” – you punch holes in one panel, and then make your own little “spot” of weld, starting in on the bottom panel and picking up the top panel as you fill the hole in a circular motion. It is as strong as a good spot-weld, and usually stronger, and this turned out well.

Many shops will just pick up the outer edge of this with 1″ runs from the MIG welder. That’s alot easier and ALOT faster, but is a bad idea because it only grabs one side of the flange, and leaves the inner, bottom-facing seam unwelded and flexible, and able to get moisture in – even if it is sealed with seam sealer…

The plug-welding is complete here. It is as strong or stronger than the original structure, and provides excellent mating of the panels.

Finished! This looks factory perfect from underneath and the from the side when viewed below the outer sill. The interior looks a litte different from the factory spot welds, but is a rock-solid repair, and is covered with carpet. Plug welding is a good solution for this repair with the car in this fully assembled state. Now it's time to do it all over again on the LH side!