That’s what I put into the title of the e-mail when I sent these photos to the customer – it’s always a little shocking for them to see things at this stage! For me, though, the removal of most of the rusted metal is making the shell look better already…

This post follows the initial dissection of the car after it was mounted into the rotisserie and braced. On this shell, we’ll dissect and prepare most of the flanges, and THEN blast, so that every nook and cranny is blasted down to white metal.

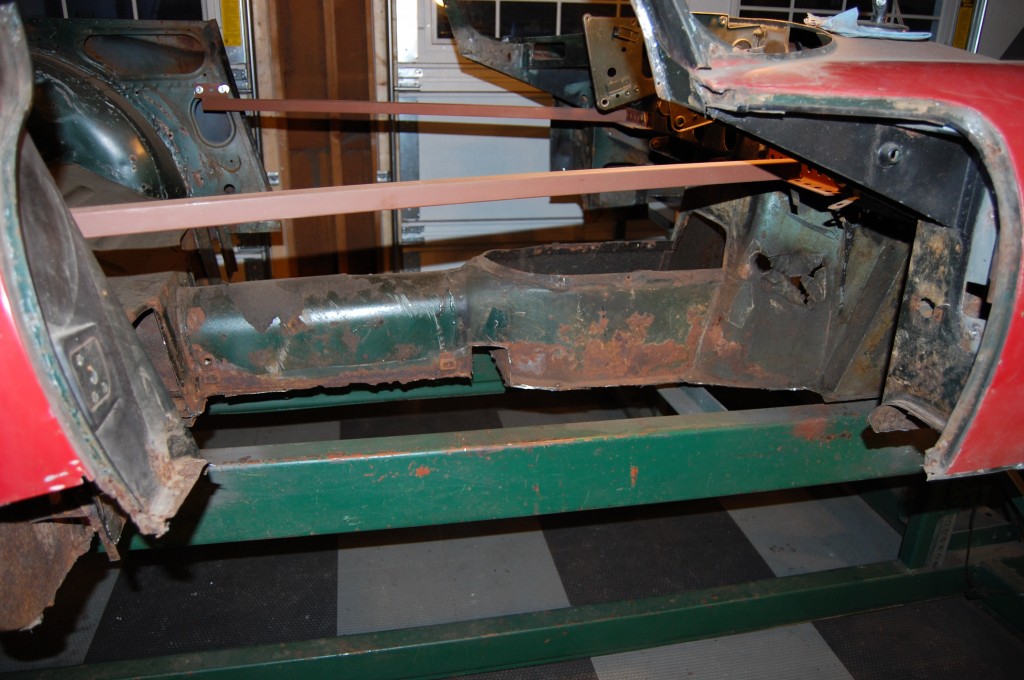

- She’s in the rotisserie now, and all bolted up tight and braced. Our rotisserie is ugly, but it’s dead accurate and rock solid – and has dozens of laser-straight E-Types in its past to prove it!

- Only the beginning – brace yourself for these photos…

- We may need to replace the inner sill…

- Major cancerous rust everywhere – most other shops won’t touch a car this far gone.

- The main support runner under the LH side was bowed upward badly – it should sit snugly against this rail when in the rotisserie. Here, you can see that it does touch at the very rear, but that I can get a finger in there further forward.

- Even further forward, we’re at about 3/4″ and I can almost get my whole hand in there, yet the forward end also touches. It’s interesting, but irrelevant – this car will be approx. half new metal when we’re done.

- Take a good last look!

- There are no words for this butchery…

- Overlapping like this is a time-bomb of decay – and a FAST one!

- Here we go! And the further you go in, the worse it gets…

- If whoever did this was just trying to fix up the car to drive themselves, they were a suicidal maniac. If they were doing this for a quick sale, then they were a HOMICIDAL maniac! UNSAFE doesn’t even begin to describe this…

- Here’s a close-up of the passenger’s seat belt anchor – I guess they really hated that person?… (OK, I just cracked myself up!)

- RH B-Post – no surprise here that we are seeing this much rust up in here based on the rest of the shell.

- Now we’re getting somewhere!

- I just can’t stand it… “Let’s use galvanized so it won’t rust this time – but let’s not do ANYTHING ELSE!”

- Below the LH B-Post in the rear of the LH sill.

- Woops! The guys in Coventry missed this flange. We actually see this at least somewhere on every shell.

- Day One of the cuttting is complete and the big pieces are out. Next, we’ll dive into the more tedious task of dressing up the flanges on the panels that are staying.

- Both floors, inner and outer sills have been removed. This is basically what all E-Types end up getting, so it really doesn’t matter how they start out. I tell customers with really bad cars, “It doesn’t matter is your floor has a couple rust holes the size of a quarter, or the floor is GONE – you’re still getting new floors and sills either way…”

- To me, this looks exponentially better already!

- We also sliced out the boot floor – it had the typical tracks of cancerous rust in the bottom of each of the three supports.

- We saved the RH bulkhead “X” panel, but will replace the left. (actually, earlier today we pulled the RH side as well during the flange work – it needed to come out…)

- When we started, I though we could save the trans and driveshaft tunnel. After today’s work, which you’ll see in the next post, I know it all needs to come out as well… But we will leave it in for reference untilt he floors are in, then we’ll pull it and replace it with a combination of new and saved panels, all re-fitted with the new floors.

- See – it’s toast… But the welded nuts in the bottom of this section are a crucial dimensional point – they are used to attach the rear trans mount. We will leave this as-is, fit the floors to this, then remove this and fit the new trans tunnel to the floors. Along the way we will constantly refer to the initial measurements of this shell, the original Jaguar blueprints and dimensioanl crash charts, and my personal favorite, the other 6-10 E-Types that are always around – that’s usually the best reference of all!