Hello!

Honestly – it has been so long since I wrote a blog entry, for a minute I forgot how to get started! Sorry guys – work and life has been very busy, and as the business continues to grow, I just have less and less time.

I was just telling Janie last week that I think my blogging time has been consumed by answering the evr-increasing volume of emails and phone calls that we get. So this morning, I tried to do something smart for a change, and instead of answering a customer’s emailed question about bonnets, I wrote it up in the form of a blog entry that I can refer back to over and over again.

So here are my thoughts on this very common question for E-Type owners and restorers. I hope some of my opinions aren’t too rough around the edges, but I’m just “giving it to you straight.”

And just to be clear – my answer to this question is not always, “Buy our stuff!” I’m always honest with people – brutally sometimes – and sometimes, it just makes the most sense to buy a “new” one… But here are my thoughts on the question as a whole, so you can work on the decision on your own. That being said, we are always happy to look at photographs of your bonnet, and help you with that decision! – Chuck

E-Type Bonnets – Repair or Replace?

This note started out as a reply to a customer who was looking for some bonnet help. But I had some time this afternoon on a rainy day to write up the thoughts and ideas I have shared on this topic now for several years in other emails and phone calls, and so I though putting this up on the blog would be a big help.

First of all, I tell everyone the same thing, and have for years now – “If you don’t currently have a usable bonnet, then you have a $10,000 problem – you just need to decide how you are going to spend it…”

Option #1 – Restoration of your existing bonnet:

This should always be your first choice – it is going to be the least money, fit the best, but also be the most work… We make and sell just about any piece you would ned to complete this work. In my head, I break bonnets down into 4 main areas:

1) The 6 “large” panels – center section, 2 wings, lower valance, and 2 inner valances or “air tubes”. We use originals for these large panels and restore them. The one caveat to this is that we only use the original skin of the lower valance, and replace the entire lower support member with our new piece fabricated here. It is available for ALL E-Types and contains all of the hinge plates, etc. – cost is $495 to $550 USD depending on the Series… For the other outer skin panels – wings and center section, we can fabricate ANY section of this that you need to repair your existing pieces. That being said, don’t call and ask for a complete new nose piece for the center section – while we CAN make it, it is time consuming and costly, and in that case, you are MUCH better off just purchasing a “new” center section (see below).

“New” examples of the 6 large bonnet components are available from the usual sources, but the quality is HORRIBLE – and seems to be getting worse instead of better…. Actually – the center sections are the best part usually – although they can be made of thinner steel that results in “waviness” that is tough to fill and sand out, and you just don’t want alot of filler in the large flat expanses of the bonnet…

The “new” lower valances are coming from a few different places that I won’t name… One brand is definitely the best of the three, but still not quite right dimensionally, and is usually too wide in the very back at the tips that meet the wings, and the main support wall is often welded in out of place – by as much as 1/2″ – which causes a real nightmare when shimming and fitting the bonnet. The #2 brand is also dimensionally incorrect and very poor build quality – with a seperate piece welded in for the forward nose section that creates alot of filler work in the forward section to “erase” this seam… Finally – the #3 brand (often sold in yellow primer) is nothing more than scrap metal – the shape of the nose section is an embarrassment…

The new wings look good coming out of the box, but they have dimensional issues that make it VERY hard to add them into a factory bonnet and fit them to the car…

2) The 5 “medium” panels – internal mouth tray, 2 headlamp diaphragms, and 2 rear mudshields. We make ALL of these pieces for ALL E-Types here, and they are EXACT. In the case of these panels, it usually makes economic sense to replace ALL of them, as their cost is typically MUCH less than it would cost to have them restored at the hourly shop rate. That is what we now do on all bonnets restored in-house… The current cost of all 5 of these panels for a Series 1 bonnet from Monocoque Metalworks is $622 USD.

3) The bonded flanges – we make ALL of these for ALL E-TYpes, and sell them in kit form or individually. While we do occasionally restore and re-use a few of these on each bonnet, it also makes more sense to just replace all of these as well. The current cost of the complete set of 14 flanges for a Series 1 bonnet from Monocoque Metalworks is $365 USD.

4) The hardware – in this case, we use all new hardware in kits from one of our suppliers. For the price (approx. $120 USD), there is just no other choice – as it can take almost a full day to properly restore the original hardware. Even when we are working on a top level concours restoration, we still use most of the new kit, in conjunction with the original GKN or Rubery Owen bolts, and the original small spring washers instead of the modern lock washers that come in the kit.

When you break it down this way, things start to look alot less daunting for restoring your own bonnet. For approx. $1,500 USD in parts from us, you are replacing almost the entire inner assembly, and then you just concentrate on the restoration of the 6 large piece, one by one… As you restore each of those pieces, strip them bare and send us photos of the damage, and we will gladly point you in the right direction on its restoration, and provide any necessary patch panels – custom made for your problem. We have helped dozens of customers restore their original bonnets in this manner, and have also blogged the restoration of dozens more on our website.

Option #2 – A properly restored original bonnet – purchased outright:

I’m pretty sure that Monocoque Metalworks is currently the only source for this – probably because we are the only ones crazy enough…

Our restored bonnets are built from restored original center sections, wings, and the skin of the lower valance – as described above. We also use original restored inner valances (the long “air tubes” and walls). Everything else is new and fabricated here – the main wall of the lower valance with the hinge plates, the headlamp diaphragms and mudshields, the tray inside the mouth, and all of the internal bonded flanges.

All original components are blasted bare – safely – all dents, accident damage, and rust problems are seamlessly repaired, and then all components are sprayed with at least 2 coats of a high-quality 2-part epoxy primer. Finally, it is assembled and glued. We actually disassemble the bonnet again after it is glued up and trial fitted – and THEN paint the individual pieces, so that all enclosed areas are covered. This results in a bonnet that is dimensionally correct, and well protected inside and out.

Option #3 – A “New” steel bonnet:

WHOLE “new” bonnets are available, and as you can guess, I am not a big fan of those either.. But that being said, if your existing bonnet is just “TOTALLED” – than they are often the best choice. Fitting them to the cars is VERY difficult and time consuming. That can actually be said for an original bonnet as well, but at least with an original you know everything is right and you are eventually going to get there with patience and care. With a “new” bonnet, you will need to do metalwork to get the job done – above and beyond the usual shimming and trimming of the back edge. And alot of body shops just aren’t capable of doing the work that it takes.

It typically takes me anywhere from 8-16 hours to fit, shim, and trim the back edge of a restored factory bonnet. I can fit ANY bonnet to ANY E-Type – perfectly – it just takes time, patience, and most of all – experience – and that’s where I have the advantage on bonnet fitting – it’s not some special talent I was born with… When you purchase a new bonnet, they will tell you at the point of sale that it takes 40 hours to fit it to the body shell. That is just insane, and this is simply their attempt to cover the fact that they just don’t fit…

But with the new bonnet, you do get something very uniform and smooth that is going to require less block sanding and prep by your body shop – the only problem is they may NEVER be able to fit it to the car! One other problm is that it is entirely coated in a very low quality black “shipping primer” – that is sprayed on after the bonnet is assembled in bare steel – so every time you remove a panel or a washer, it is bare steel under there – NOT good. Most professional restoration shops take the time to strip this all off completely and start over with a higher quality primer.

One of these new bonnets can cost anywhere from $8,000 to $11,000 depending on who you buy it from, but regardless of where you get it – they all come from the same place… On the plus side – when you buy a new bonnet, you do get a crate for free…

Option #4 – An aluminum bonnet

There are a couple of different source for aluminum bonnets. MOST IMPORTANT – these aluminum bonnets, while works of art in their own right – have no business on a road-going E-Type or a show car. Most of the aluminum bonnets available for sale in the US all come from the same supplier. These are handmade and while the craftsmanship is good, the patterns that they are using are not, and there are definite differences here – ESPECIALLY on the inside. When painted, they WILL look the same on the outside, but ABSOLUTELY WILL NOT look ANYTHING like an original bonnet on the inside – not even close… So don’t believe it when you read “looks the same when painted” – that is abosutley not true… On the other hand, for a high-perfomance E-Type or a racer, these are a nice piece – and in those cases, the differences are acceptable. I have used one of the bonnets from this source for this purpose and after a few “improvements” to the inner structural differences, etc., it was a great choice for that non-stock car…

There are at least two sources of aluminum bonnets built in the UK, and these are an even higher level of craftsmanship, better built with more correct patterning, and much closer to a pure aluminum copy of a factory steel bonnet. There are still differences between these and a factory steel bonnet, but they are minimal. Of course, these bonnets cost MUCH more than the other aluminum bonnets, but they are SWEET! But again – only for a high-performance road car or a racer – NEVER a daily driver or show car.

Conclusion:

I hope this helps some of you make the decision – it can be a tough one and you just have to weigh the pros and cons… Don’t forget – you ARE spending $10,000 – there is NO EXCAPE from that fact! Whether is is in repair pieces, new panels, new bonnet, crating, shipping, fitting, your own time – it is all going to eventually add up to about that $10k… So decide how to spend it wisely – and what the best way is to spend it for YOUR E-Type.

NOTE: The one thing you should NEVER do is buy another “good used” bonnet on eBay, etc. When you get it, it is going to be a rusted, undercoated, bondo-filled mess just like what you already have now… I know it LOOKS great in the photos, but I can read an eBay photo of E-Type bonnets better than anyone, and even I have been burned! You’ll just end up spending $1,000’s on more junk that is no good to you in its current form….

The upshot is that in 30 years of E-Type body shell restoration, we have found over and over that NOTHING beats a properly restored original bonnet – and if it is YOUR original bonnet – that is even better. And so if there is ANY way that you can save yours – or at least MOST of it – that is going to be the best bet in the long run…

- With the right tools and some patience, even a train wreck like this…

- …can be properly reshaped back to this…

- …and eventually be a part of this!

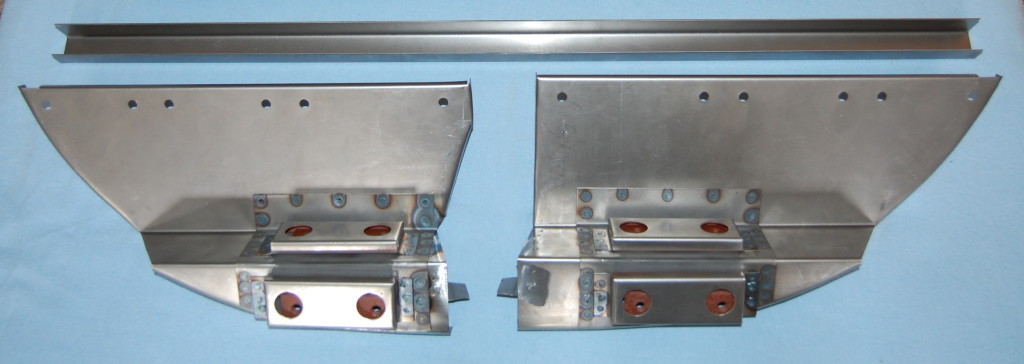

- These are Series 1 inner valances – one of the 6 large bonnet panels that we restore as part of a typical bonnet restoration.

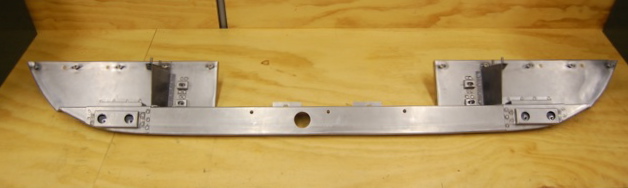

- This is the new lower valance support member – this piece combined with your original skin is THE BEST solution for a lower valance – all of the “new” lower valances have major fitment and shape issues.

- This is the Series 3 V-12 version of the lower valance support – we make this piece for ALL E-Types, and it costs about 1/3rd of what a new lower valance costs as well!

- This is our complete bonded flange kit for a Series 1 bonnet. Cost is $365, and it is money well spent when you consider the amount of time it takes to restore your originals. Also, you KNOW these are the correct shape when you purchase them from Monocoque Metalworks!

- The Series 3 V-12 bonded flange set – contains less pieces since the inner valances walls are directly bonded to the center section without flanges on a Series 3 (which makes them a MUCH bigger paint to reassemble, glue, and prime!)

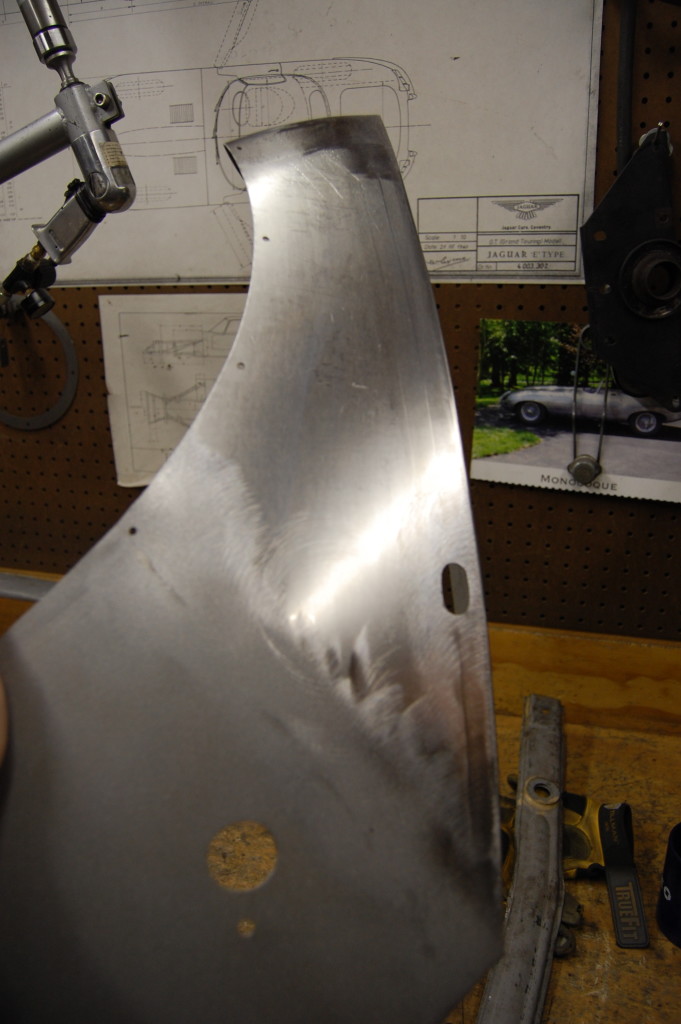

- This is a popular repair piece that we make and sell for all E-Type front wings – this is the lower section of the rear of the wing, between the wheel opening and the bulkhead or firewall.

- An interior view of the same piece above shows the care we take in the forming of the wired edge.

- These flanges are full-length repair pieces for the main side flanges of the center section and wings. E-Types often rust badly in these flanges in the area above the front wheels. These long flanges will allow you to cut out and repair that rot, and also get the proper arch back into your center section and wings – which is CRUCIAL!

- Here is a collection of custom repair pieces that we made for one customer based on photos they sent of the particular damage in their bonnet.

- This is an example of an otherwise excellent original Series 2 wing, where we cut out the badly damaged fron section and replaced it with a perfect repair panel. The end result is a wing with PERFECT factory dimensions, that will “play nicely” with the rest of the bonnet during assembly. Replacing this with a “new” wing instead would have cost 4 times as much – for a panel that simply DOES NOT FIT!

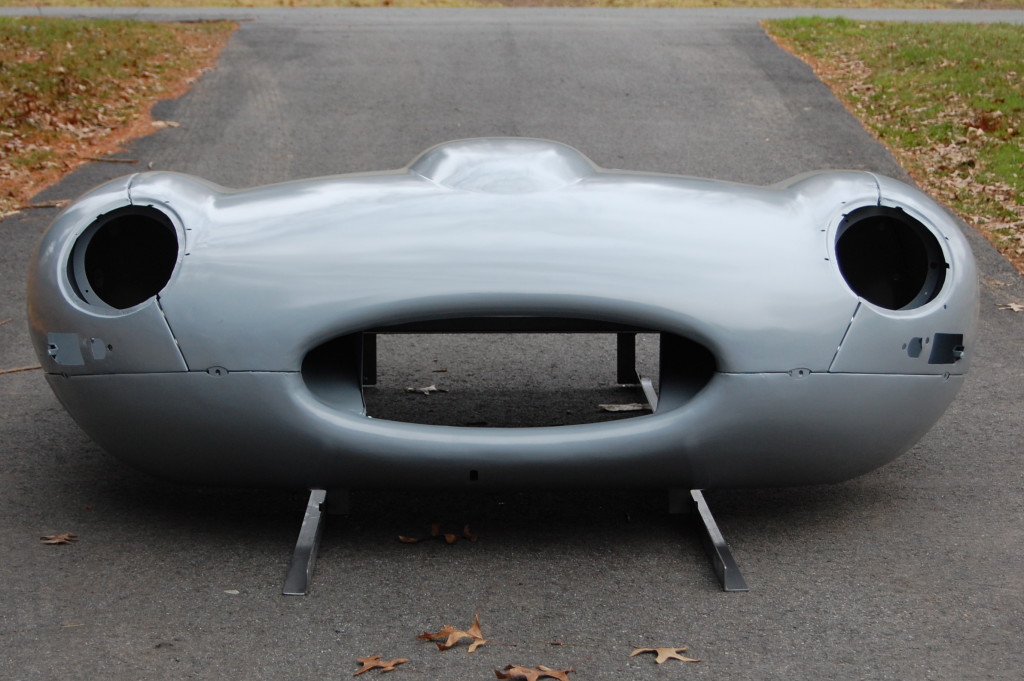

- This is an example of an original bonnet restored here at Monocoque Metalworks. When you purchase a restored original bonnet from us outright, this is what you can expect to receive.

- Here is a shot of the interior of that same bonnet – this is where all of the real work is!

- This particular bonnet was undamaged, and a great core, but with ALL bonnets that are restored here, we are absolute FANATICS on getting the correct shape back into the mouth.

- Another shot of that same bonnet – all panels are liberally coated in 2 coats of a high-quality 2-part epoxy primer – BEFORE it is assembled. It is now ready for final paint to be applied in the assembled state – as it was at the factory – and incidentally, is

- Here is a “new” bonnet, fresh out of the crate…

- This is an example of the poor build quality on the “new” reproduction bonnets. This wired rear edge of the lower valance is shaped all wrong, and when viewed from this forward angle, looks horrible… This is supposed to be an inward curve, NOT a straight line…

- This is how the “new” bonnets are doctored up when they have dents and issues, etc. Here, a pick hamer has been used extensively, and this area inside of the wing will need a bit of filler and smoothing. Now, our restored original bonnets will also need some filler in this way, but we don’t violate them with a pick hammer like this! AND – one of the whole points to a “new” bonnet is that you should not have to deal with this type of thing!

- Another classic shot from a “new” reproduction bonnet. You can see that proper alignment of the panels is quite lacking…

- …and, another major issue with “new” reporduction bonnets is the poor priming – which is done AFTER they are assembled. That is ALOT of bare metal to be rusting a few years down the orad – OR – as shown in the previous photo – already!

- This is a new aluminum bonnet from the same European manufacturer that sells these wholesale to most of the US suppliers. It is a very nice piece of fabrication work, but the mouth is not “quite” right – although it’s very close…

- On the inside, things start to break down as far as”correctness” – note the rivets in the inner valance wall, etc. Also note that the bonnet is made from several large pieces of aluminum that are welded together and then dressed down, unlike the original steel bonnets pressed from one large piece of steel. This is typical of a handmade piece, and acceptable for a racing pieces, etc., but it is certainly NOT “just like the original when painted” as is often advertised.

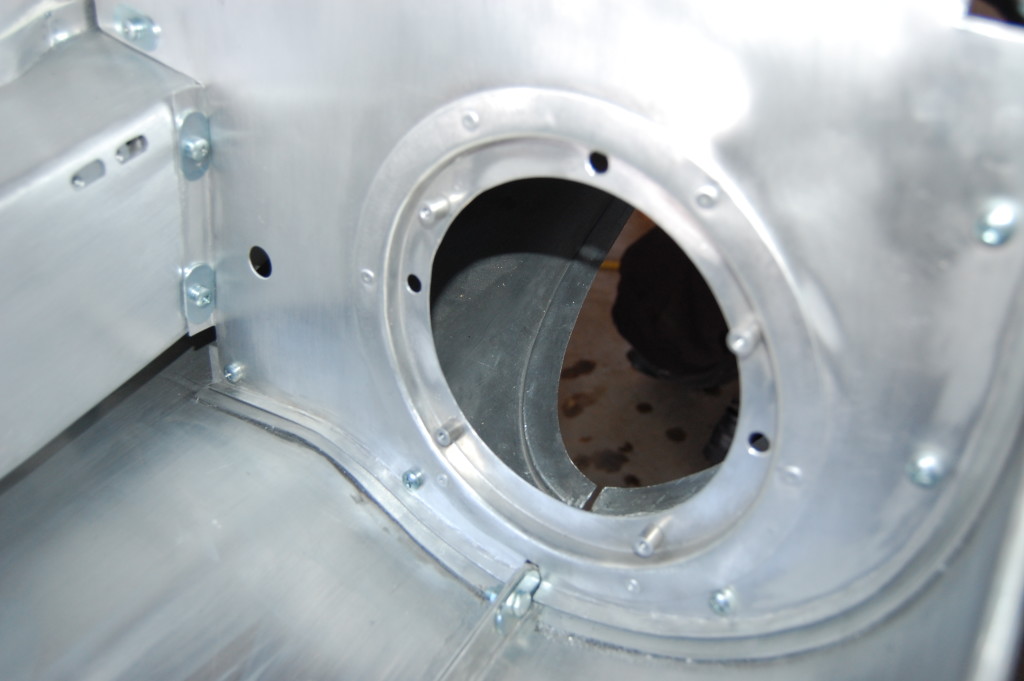

- The headlamp ring in the forward diaphragms is – again – a well-made, functional piece, but NOT anything like the original in looks, dimensions, or the riveted attachment…

- You probably can’t tell from this shot, but this RH rear mudshield LOOKS like the original, but the actual shape of it is WAY, WAY off! And this just drives me crazy, since it is the same amount of work to make it correctly and thi is just bad patterning. I want to be totally honest – the men who made this bonnet are better metalshapers than me – there is no doubt. However, I just don’t understand why theyfall down so badly in the patterning…

- Rather than spot-welded, this rear wing support is MIG welded to the skin with an aluminum spool gun. That is OK for a high-performance piece, but again, NOT identical to the original when painted. The aluminum is also about 50% thicker than the steel, and that shows up clearly when painted as well.