Many years ago, I began patterning and fabricating parts for building complete NEW E-Type forward bulkheads. Unfortunately, the whole project went WAY onto the back burner when Monocoque Metalworks really took off…

Soon, we are going to finish that goal, and build some complete, NEW Forward Bulkheads. It is a BIG job, and the complete assembly consists of DOZENS of complicated pieces, not the least of which is the firewall itself. Reproducing the shallow dishes in the firewall became a challenge back then that I absolutely REFUSED to throw in the towel on – despite several failed attempts at creating tooling and a process to make the shapes EXACTLY like the original panel.

Finally, I conquered the shape, and made up some tooling that accurately reproduced the one smaller hole on the RH side of the firewall – located in the very spot where American market E-Types were often fitted with an aftermarket Air-Conditioning unit – which I believe was often dealer installed – apparently with little more than a drill and a can opener!

Then the project stalled, and I never moved on to making the additional tooling needed to make the recess on the LH side of the firewall, and the wider one in the center – but I’m happy to say that it is now underway at our machinist and should be completed within a week or two!

I got back onto this because a couple of weeks ago, I received not one, but TWO calls about badly damaged firewalls on early Flat-floor 3.8 E-Types. As usual, we were backed up in the fabrication shop, and I SHOULDN’T take on new custom jobs like this, but I just could not resist getting back to one of the more fulfilling pieces that we make here!

So I made some REALLY cool patches for both of these E-Types, and finished up the patterning and tooling in the process. And for those of you who are waiting on me to work on your shells or bonnets, I technically didn’t steal the time – I did it on the weekend – for “fun”…

Enjoy! – Chuck 🙂

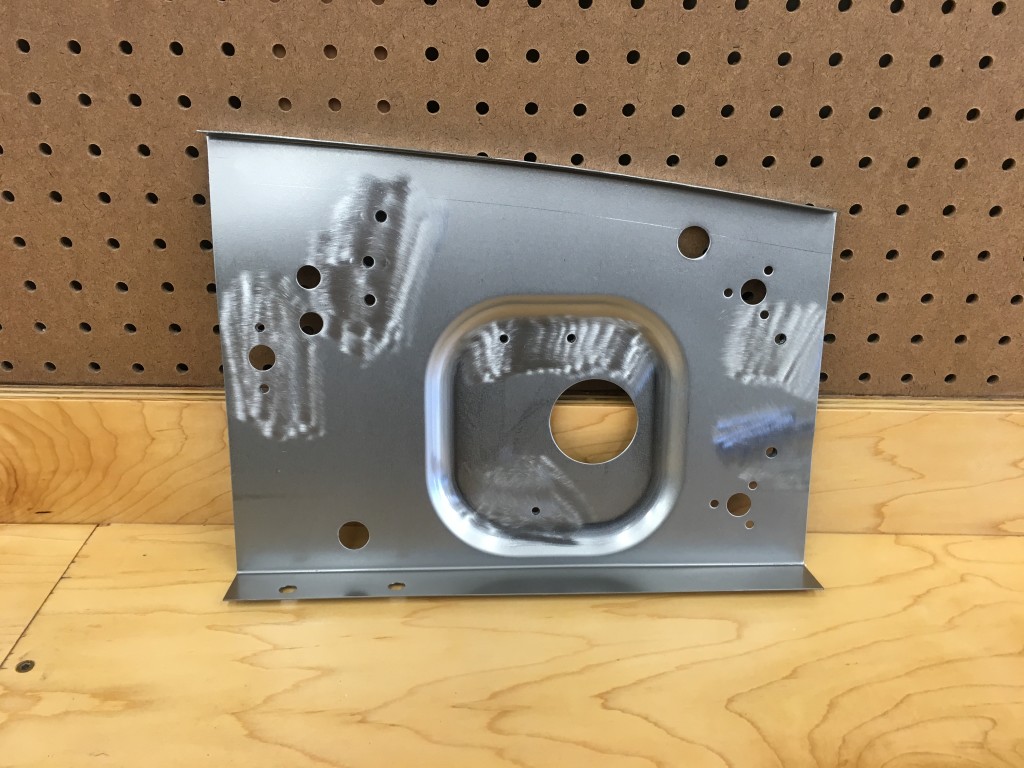

- Here are the patches that we created last weekend – for 3 different cars – 2 3.8 flat-floor OTS’s, and a 1966 4.2 Series 1 FHC

- Another shot of the new pieces – something about that little recess just makes these seem “over the top” from a coolness standpoint = I LOVE doing this piece!

- This is a photo sent in by the first customer. This is a late 1961 OTS that was actually quite solid overall, but with this problem… I have ssen this before, and it is the result of a rodent’s nest inside of the bulkhead. The mouse or chipmunk or whatever urinates into their own nest all Winter, creating an “acidic sponge” that eats through steel like crazy! Have no fear, I KNEW I could help here!

- And here is my solution! My plan here is for the customer to splice this piece into the existing firewall along the RH and bottom edges of the hole for the wiper box. This means that the patch panel will be well supported by the side panels of the wiper box, and will also only need to be butt-welded along a short 2-inch or so section below and to the left side of the wiper box. I did not cut out the wiper box into my piece so that they can fit this up to their existing bulkhead and trim it to fit very precisely.

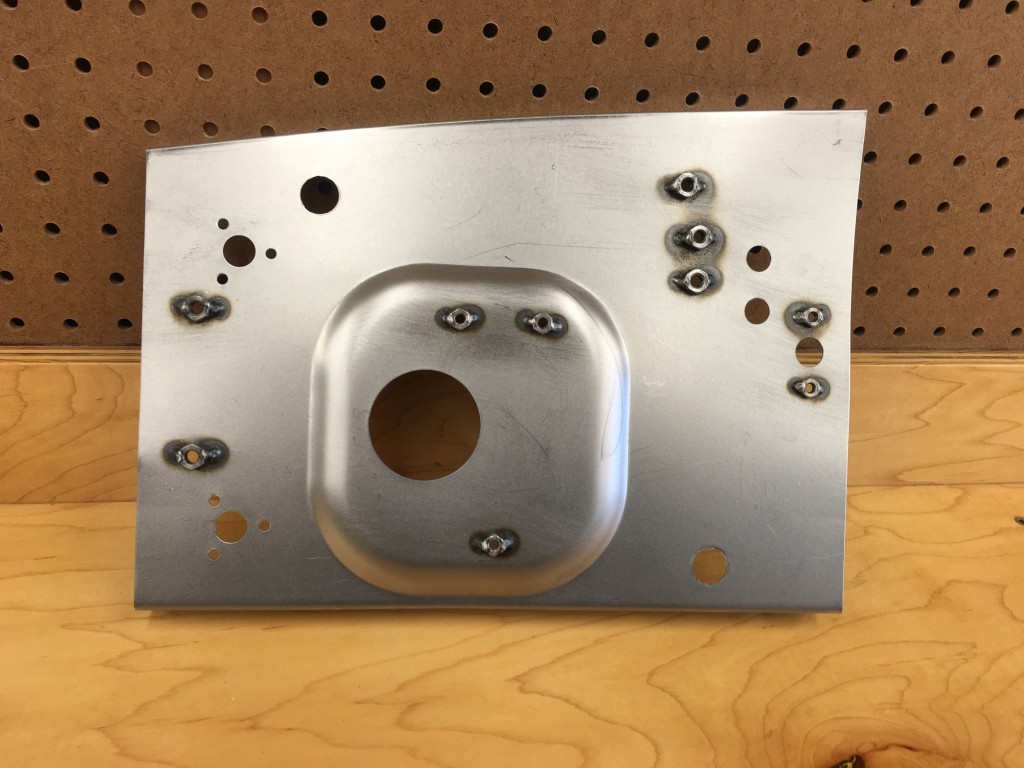

- Here is the back side of the same panel, showing the nuts welded into place for the washer bottle mount and throttle linkage.

- Brent is holding the panel up to the firewall of another late 1961 OTS in our shop currently – that was VERY close in number to the customer’s car – which was very re-assuring for making sure that each hole was the proper diameter and precisely placed.

- And here, he is holding it above the firewall of the SUPER early 1961 FHC in our rotisserie – LHD car #43!

- Next challenge – WOW! This is a VERY sad bulkhead from an even earlier Summer 1961 built OTS. This bulkhead was from a car that was shoved aside in a large collection, and sadly, cut up and used for patch panels for another E-Type! AAAAGGGGHHHHHH!!!!!

- But have no fear – in addition to supplying ALL of the missing tunnel panels for that shell, we also made these firewall dish patches. This is the RH side for a 3.8…

- This is the same panel, from the back.

- It is designed to again go from the RH edge of the wiper box, to the start of the RHD brake bottle mount (that is the spot-welded bracket on the outer edge of the firewall – on LHD cars, this doesn’t do anything beside sit there…)

- See – fits like a glove on the ’61 OTS in the shop!

- And here is the patch for the other side. I told you guys that I would start admitting more of my mistakes than are typically shown in the blog, and this panel does have one – hang tight for a few photos and I will show you…

- Here is the back side of this piece – lots of welded nuts, and these locations need to be EXACT!

- And speaking of exact – here is the issue… I make these pieces using a large pattern of the entire firewall. I made up one pattern for both the 3.8 and 4.2 firewalls, and have notations on them for which holes are for which model. You would think that they would be very close, but there are actually ALOT of differences – in hole SIZE and in hole PLACEMENT, and after completing the panel, I realized that I missed one of the differences – DAMN! This repair panel for a 3.8 flat-floor roadster (which is what the red car here is as well…) has the lower heater pipe hole in the proper location, but the upper hole is off by 1/2″… On the 4.2-liter cars, they moved the upper heater pipe end over by 1/2″ to fall directly in line with the hole below it – and I did not pick that up in the patterning years ago – OR maybe the later 3.8 firewalls are like this too… Either way, this patch panel has that upper heater pipe hole 1/2″ too far toward the center of the car. I spoke to the customer and based on the damage, he can still use this and just work around that hole when piecing this in – PHEW! Still hurts my pride though!

- And finally, here is a VERY TYPICAL 1966 4.2 FHC with the aftermarket AC carnage we typically see over here in the US on late 4.2-liter Series 1 coupes. YIKES – these guys were butchers!

- But have no fear – our perfect patch is here! Note that the 4.2-liter cars do not have the large hole in the center of the recess that was for the earlier 3.8 brake bellows.

- In addition, the 4.2 version of this patch also has two 1/4″ holes with welded nuts in the upper corner that the earlier cars do not have. I THNK it is a RHD throttle linkage mount…

- The panel being held in place by Brent – this one will be installed here by us – SOON!