What an adventure!

Time was running out last week, and I had to find the time to finish the bonnet in time SOMEWHERE, so I did something I’ve never really done before in 42 years – I basically just stopped sleeping altogether…

Now, keep in mind that I’m a guy who NEEDS a good 8 hours of sleep a night. No more, but certainly no less either, and when I do 2 or 3 nights in a row of say, 6 hours, I start to get “weird”… Well, as the clock ticked down last week, I just had to keep going – and trading sleep time for work time was the ONLY way to get it done. I guess I could have let the date slip into next week, but they really needed to get the bonnet onto the car, and all I kept hearing in my head over and over was me saying “Don’t worry – I won’t let you down” when I picked up this bonnet in December.

So, Saturday night, I slept 8 hours, Sunday – 4, Monday – 7, Tuesday – 1.5, Wednesday – 6, Thursday – ZERO. When I finally got into bed at our place in Upstate NY on Friday morning at 7AM, Janie said, “How did it go?” I said, “Good – it’s on there.” and then slipped into a coma…

We finished the bonnet at 4:00 on Wednesday afternoon. Brent and I carried it outside, weighed it (58 lbs.), took some photos, and then loaded it onto the truck. I did take it easy on Wednesday night, and finally fell asleep at 11:00.

On Thursday, I got up at 5:00 AM and drove to Donovan Motorsports. Thankfully, the drive was uneventful and I arrived at just a little after noon. Brian was happy with the bonnet, and we wasted no time getting it onto the car – at which point the “fitting adjustments” started right away. First, there was an oil cooler mounted in front of the radiator that I never saw when I picked the bonnet up – it was off. Luckily, the adjustments we had to make for that were minor, but we still spent a few hours on it, taking the bonnet on and off a hundred times…

Next, we had to get the back edge fitted, and get the rear sections of the wings wrapped around to meet the sills. This was a real battle that I did not see coming… The wings were flared so heavily, that when the bonnet was here, it just kind of had the rear of the wings way out. You could pull the back adges in to standard E-Type width, and so I figured everything would be OK. Well, what I failed to realize was that we needed to pull the rear section in to meet the sill all along the sill. Getting that back edge in was easy, but getting the part right behind the wheel in all the way to the sill was TOUGH! Luckily, the pattern for the new wing was perfect, and as we forced that rear section in, it flared that wing out to be a perfect match to the rear and the LH side.

Then the flanges started bending and tearing… Nightmare. I made them here from the same .050 soft aluminum as the rest of the pieces, and it just was not thick enough for this abuse. Luckily, Brian had a piece of about .070, harder aluminum sheet laying around, and we used his shear and brake to make some new flanges and fit them into place.

Of course, this takes time, and soon it was 6:00 PM, and everyone except Brian and I were long gone. At this point, based on less than 8 hours sleep over 2 days (and working like CRAZY when I was awake – or driving several hundred miles), I really have no explanation for why I didn’t drop dead right then and there in his shop. I guess it boils down to just the shear will of wanting to get this done and do a good job for them, but it may also have been this:

I spent from 6:00 PM to 12:30 AM with Brian, working feverishly to fit the bonnet, and the whole time I kept quizzing Brian about racing, his business, his first E-Type, etc., and the stories were FASCINATING! 25 years of racing E-Types had yielded stories that involved just about every name in vintage – or recent – racing that you could imagine!

And so I just worked away at a feverish pace, and we finally got the bonnet fitted well enough to go racing, and I pulled out at 12:30 AM pretty proud of myself for getting it done.

Then (insanely…) I drove from Lenox, MA to the St. Lawrence river through the night…

Here are some photos coming down the home stretch. I’ll try to put a few captions on but I will keep them short. Stay tuned – I’m headed back up there on Friday morning to see this car at Lime Rock at full speed!

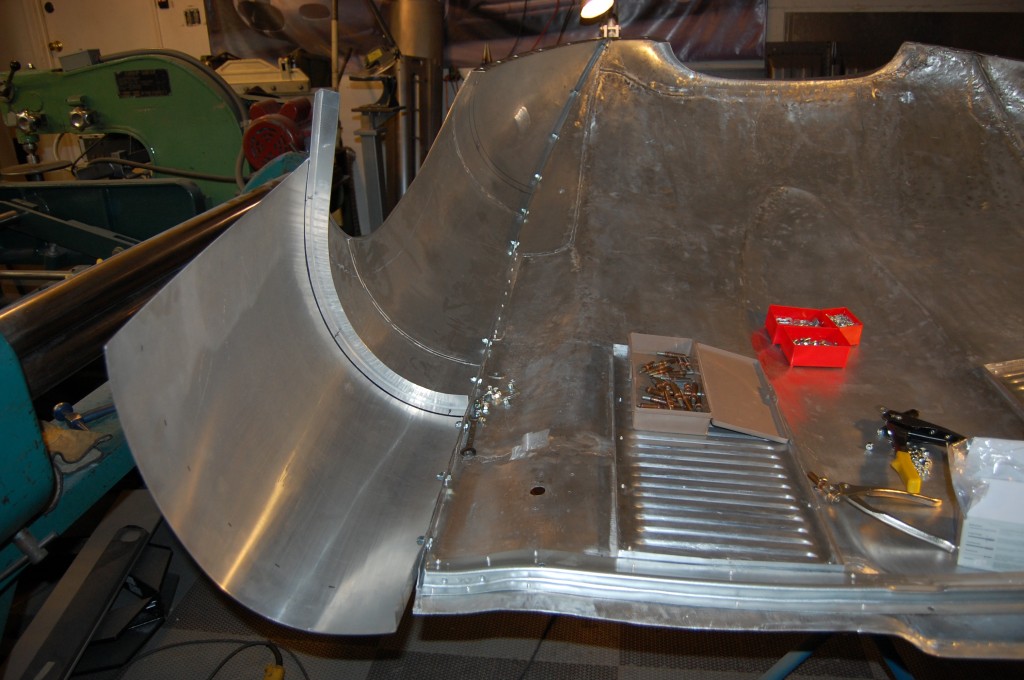

- 8:00 PM Tuesday – Final Assembly starting.

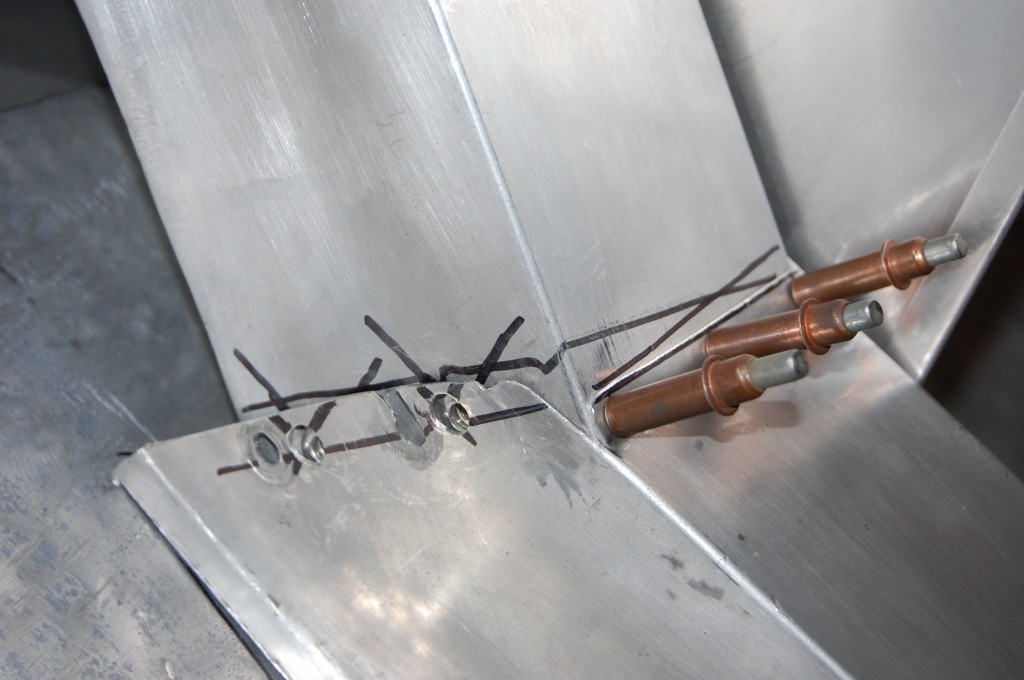

- 9:00 – louvers and steel rear support are riveted into place.

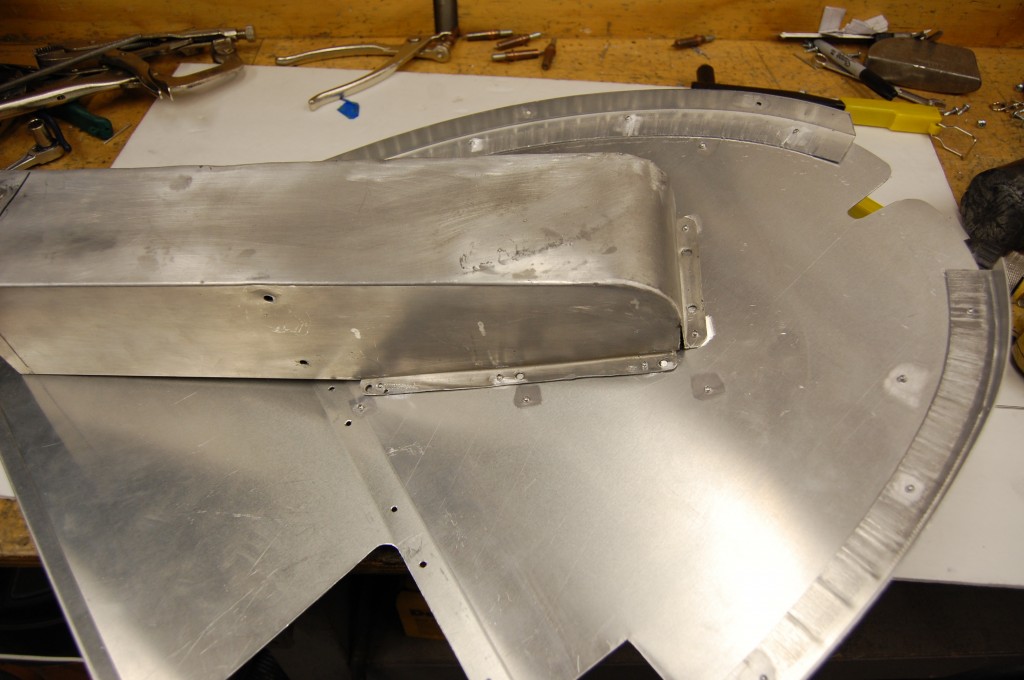

- Time for the new wing.

- I used steel here because the aluminum one was TOAST, and we needed the shape and support back here. The weight difference was less than 1 pound.

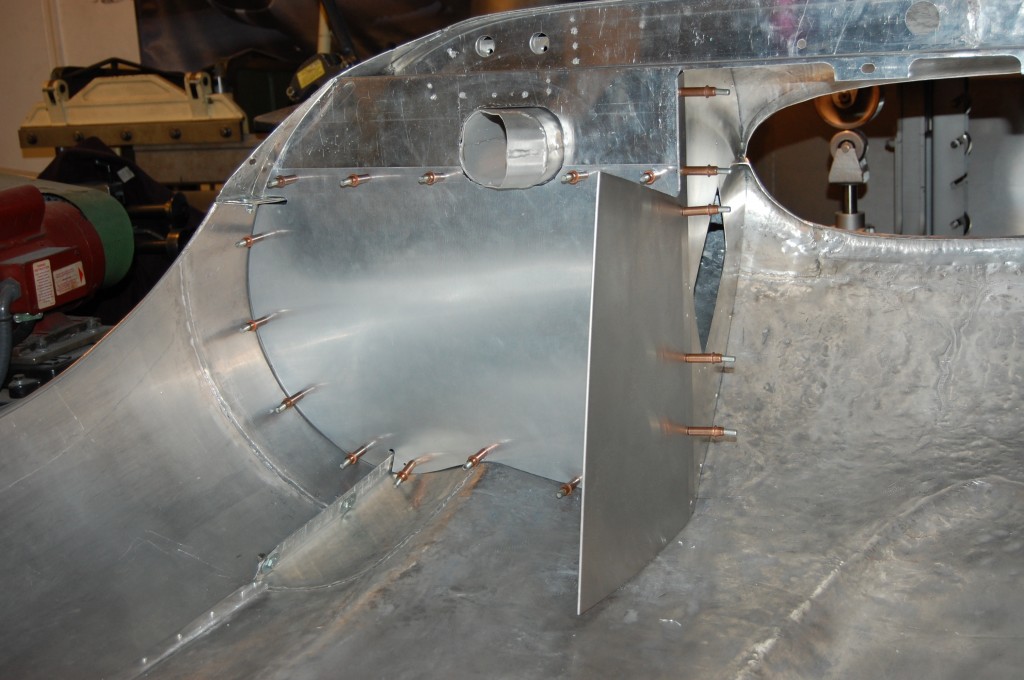

- New RH wing going on.

- This was around 11:00 I think…

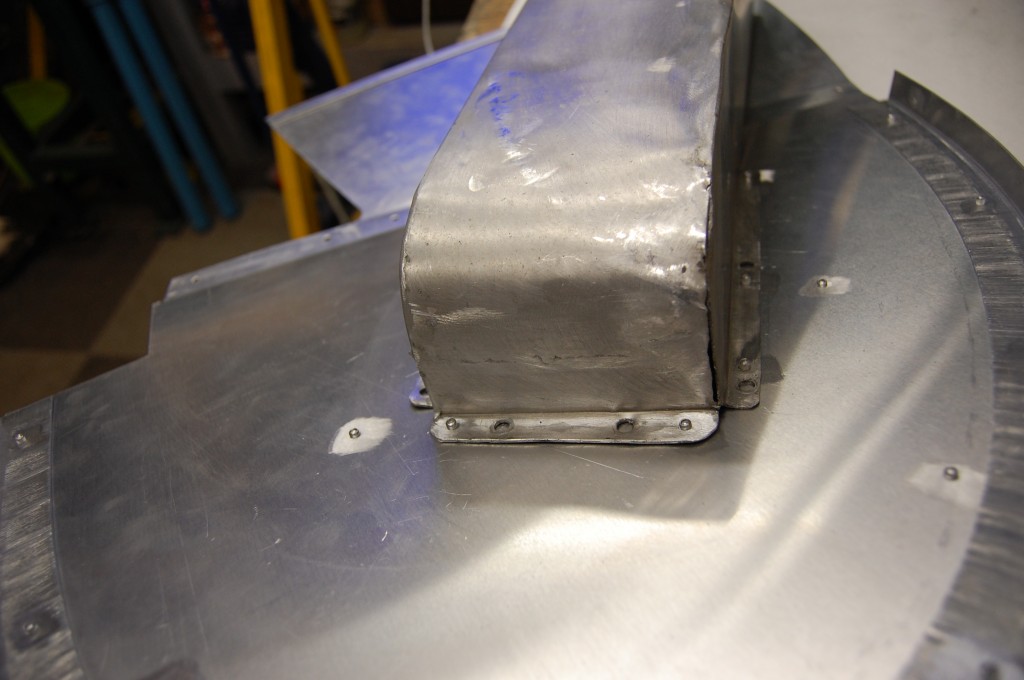

- I decided not to weld the brake ducts back in, and instead welded on these flanges to rivet them into place. I built the bonet back up with the idea that it could be taken back apart after the next wreck…

- Time to put the inner structure into place.

- It’s getting late, but we’re getting there!

- This side gave me trouble… After getting the wings and lower valance bolted up tight, the bonnet threw a kink into itself and deepened this valley some. You can see where I had to adjust this panel a bit…

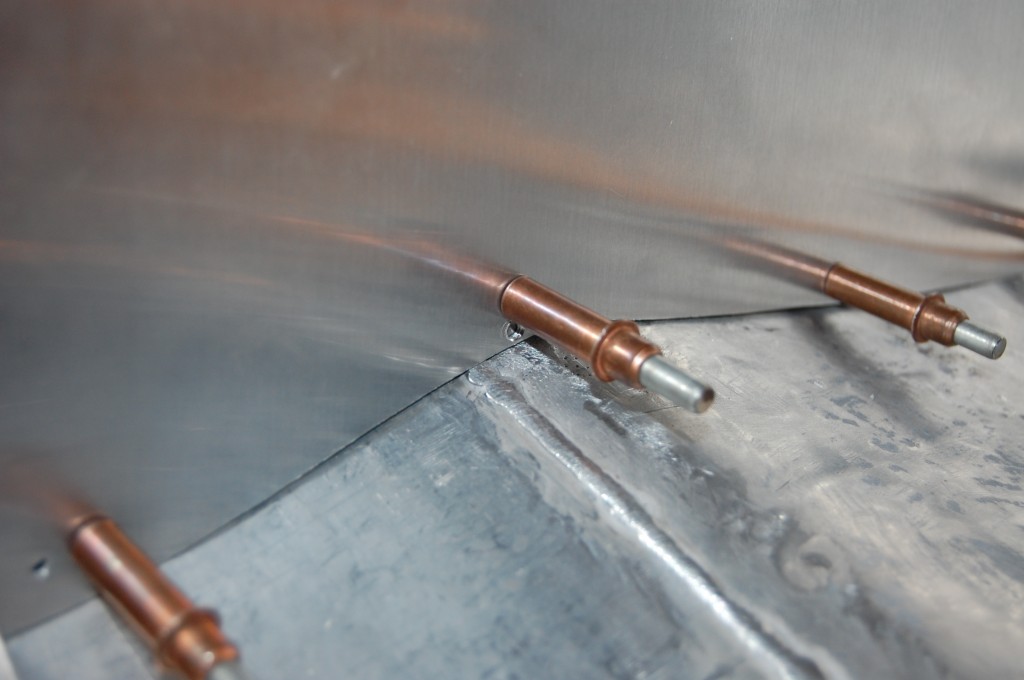

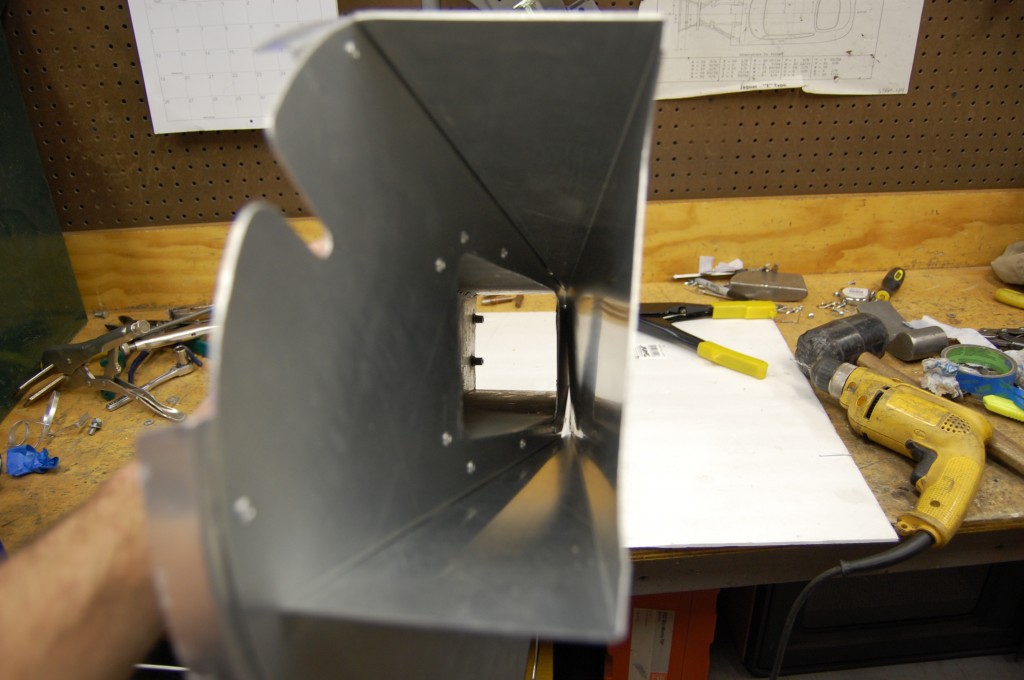

- Next it was time to finish up the fresh air ducting.

- I straightened out this duct and positioned it. That all took longer than I expected – big surprise…

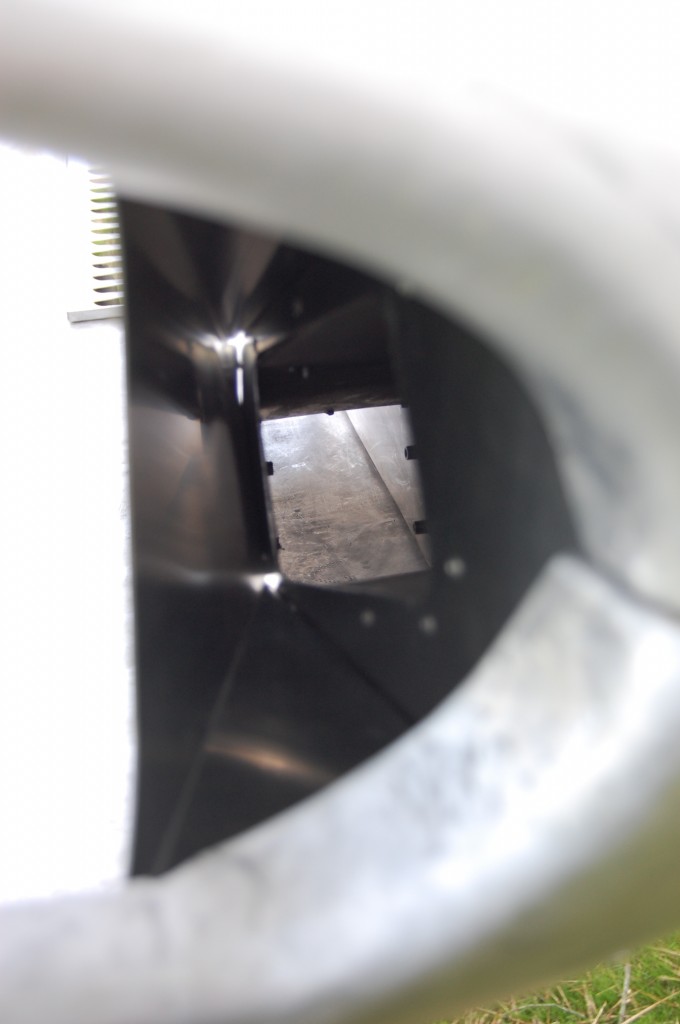

- OK – the first two of 3 duct piece are in – and I have notched the diaphragm panel for it as well – THAT took a long time too – of course…

- Then this nightmare… It’s not totally unexpected – it happens on steel bonnets too – when they are badly wrecked and hammered back into shape. Sometimes you have to do more work and “re-fix” things after it is bolted together. The smashed (building collapsed on it) V-12 bonnet did this to me last Winter…

- NowvI have handled that problem without opening up the inner structure panels again – Thank God!

- She’s still not done – but I’ve had it. This is where I called it a night, and went to bed.

- 10:00 AM – Brent arrived at 9:00 and cleaned the shop while I took a shower, made coffee, and tried to get my act together. Then we got right to finishing up. Here, he is making a rear support flange for the LH wing, and using the RH as a pattern.

- Meanwhile, I spent a couple hours getting this third and final piece of the fresh air ducting fitted. Everything is just a bit out of whack based on where it was before the wreck, but it’s close enough.

- This WAS glued into place, but I have used bolts and rivets in the front, and two small rivets here in the back.

- 4:00 PM – Wednesday – she’s DONE! I hugged Brent…

- 4:00 PM Wednesday – Here is the “Victory” shot – ONLY possible because we toom about 25 POUNDS of paint and filler out of this old girl!

- 1:00 PM Thursday – we’re beginning the fitting process, with the #62 car all prepped and ready for the race in the background.

- Here is the #61 car, complete with the surprise oil cooler. I walked in the shop, took one look at this, and thought, “GULP – Oh Shit…” But l;uckily, my new inner supports and structures were patterned off a combination of what is factory correct, what they looked like when I got it, and what I thought they once looked like. I also was careful to put things where they were, or farther forward. So while we did have to make sdjustments to fit this cooler, it really wasn’t that bad.

- 12:15 AM – Friday – it’s on there! AND – everything clears and fits – including the MASSIVE tires!

- Here’s Brian Donovan cleaning up after me – tools, patterns, scraps, rivets, nuts, bolts – stuff was just dropping and flying everywhere while we worked at a feverish pace to get this done!

- Well – she’s back together – at least the body is! Getting and engine into here before next Friday would be nice! Good Luck, Brian – see you at the track!