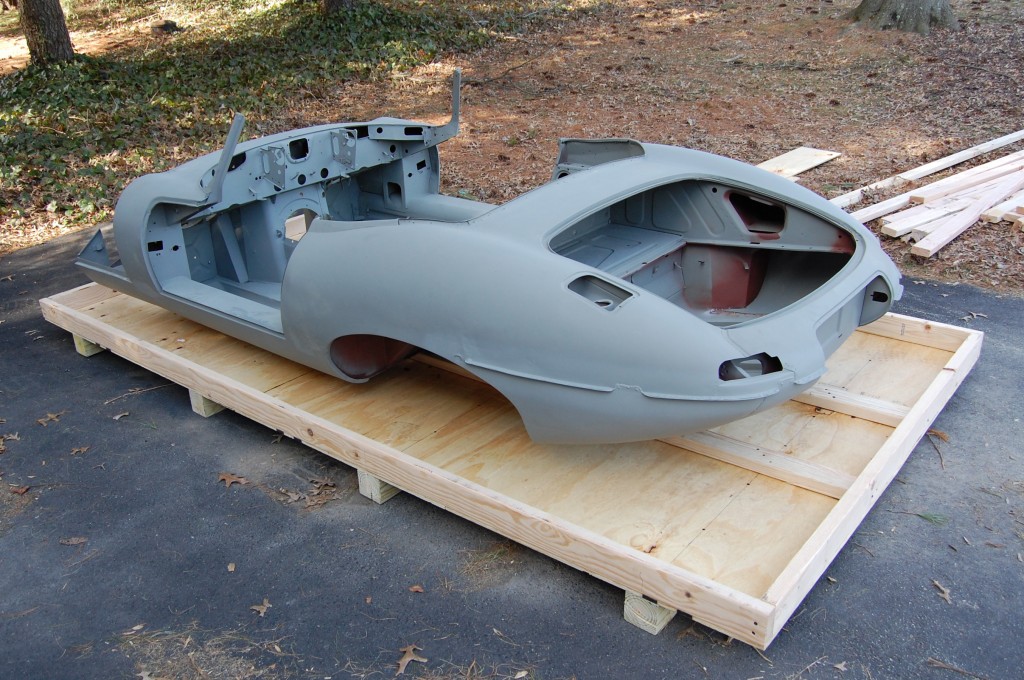

OK, we’re starting to get somewhere! Next, since we had finished up the additional bonnet panels that the customer added to their order, we could finally crate and ship this 1965 roadster shell. Building a crate like this is no small task – this one took 9 solid hours! I probably overbuild the crates, but after I spend weeks (sometimes months) on these shells, I DO NOT want them screwed up!!!

- You can tell from the angle of the sunlight that it is early morning in this shot. This is the shell, plus the two wings and inner valances they ordered. We need to pack this up, plus the doors and decklid, and some smaller panels and flanges. It is being shipped to Calgary, Alberta, Canada,

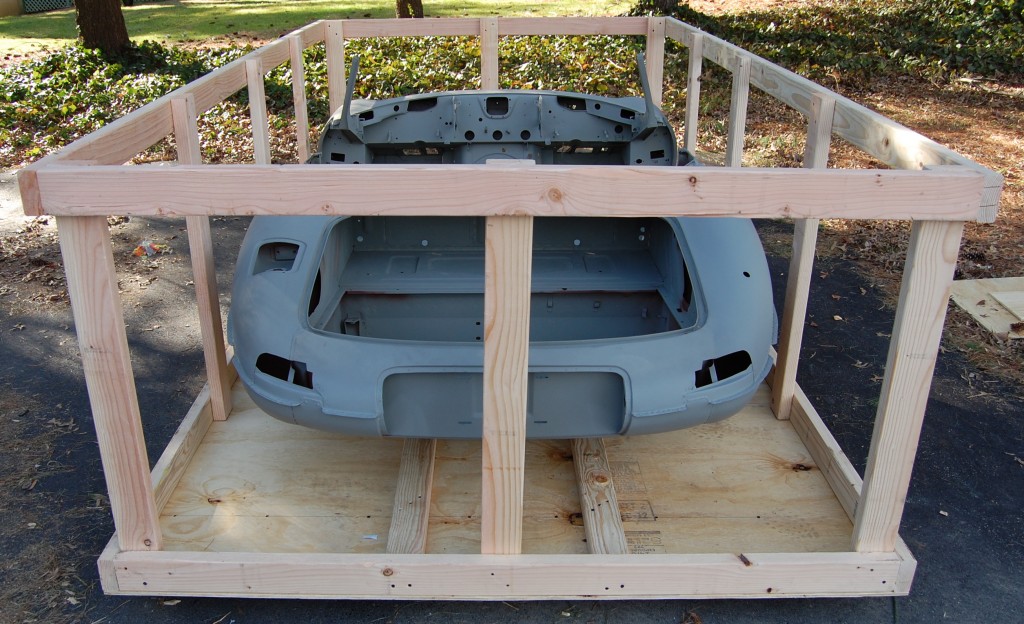

- Step 1 is to build a platform that can be safely forklifted.

- We align the main runners with the longitudinal members under the shell’s floor, and then screw the shell right down to the platform with lag bolts through two factory jigging holes.

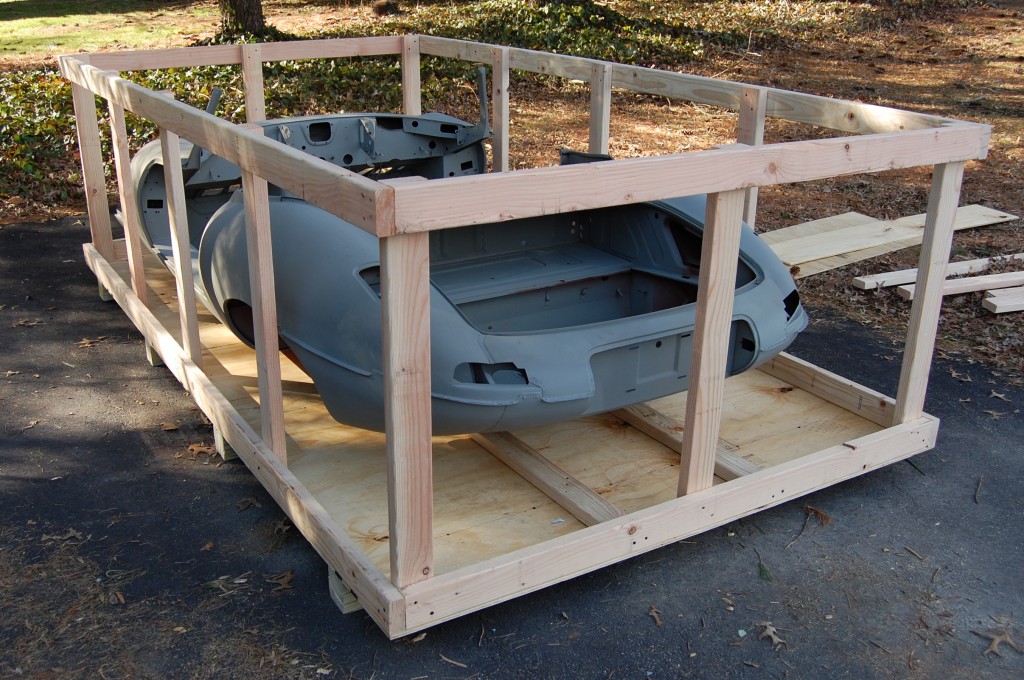

- Next, we start to frame out the walls.

- By the way – this WAS a Series 2 when we picked up this shell last Spring in Connecticut…

- We converted the tail and the doors and door shut face panels to make it a perfect Series 1 shell.

- There was nowhere to bolt the rear down, so these straps were used to keep it down and from shifting side to side. They will work fine and not hurt the shell.

- Next, we add some additional framing to stiffen the crate further, and provide framework for the walls.

- We’ll be packing the wings and other panels safely into the space in and around the shell, with LOTS of padding!

- Darkness falls, and we’re still at it…

- She’ll be safe and sound in here!

- Well, this monster box is out in the driveway in front of the shop, but here’s ANOTHER shell that is out of the way for construction!