Now it’s time for a Monocoque Metalworks specialty – the hidden subframe! No more chipping of paint along the rear door edges for THIS roadster – after we complete this modification, this E-Type will be stiffer than 99% of the vintage racers out there!

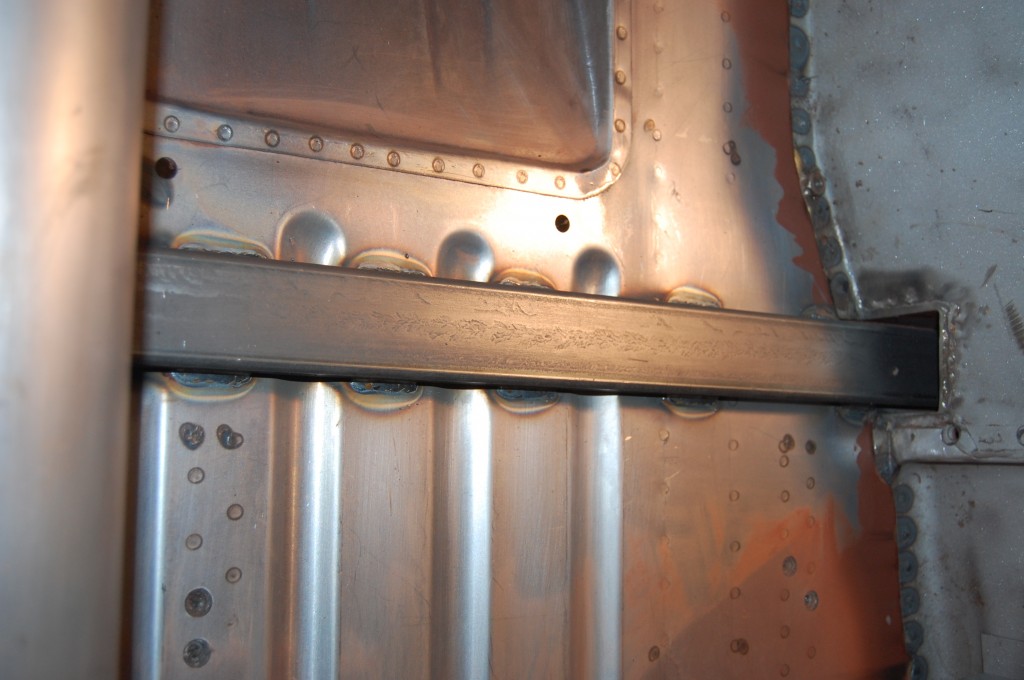

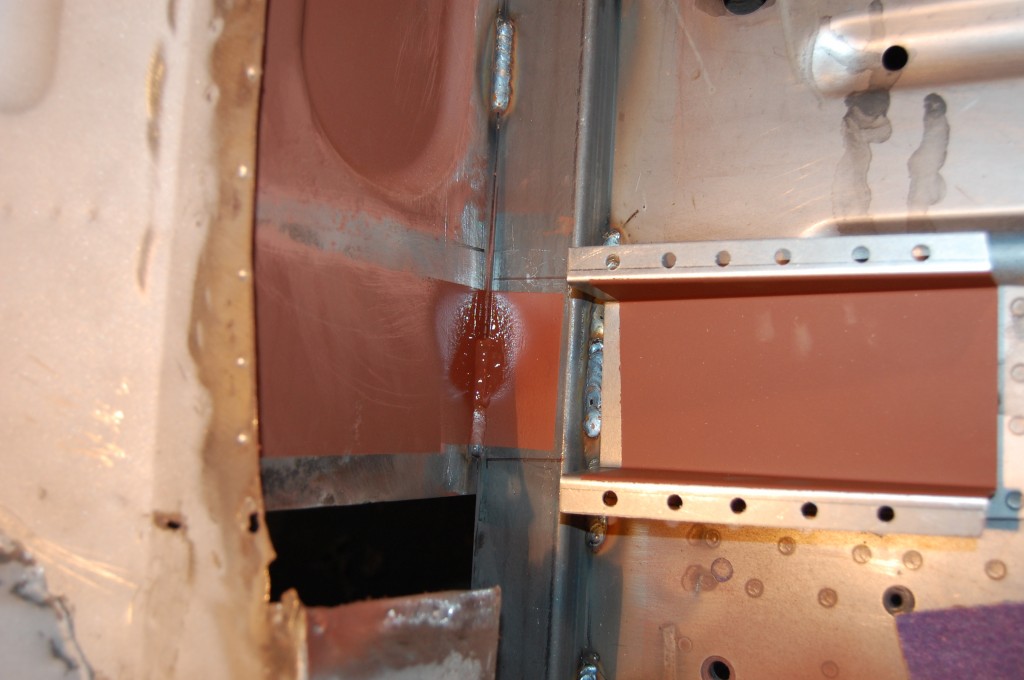

- Step 1 is laying a rail into the bottom of the inner sill. We coat as much as we can without contaminating the weld area. Once the rail is welded in, we’ll go berserk with red oxide in here and it will run down in between here and coat the rest after it is welded. This tubing is 1/8″ thick – roll cage strength.

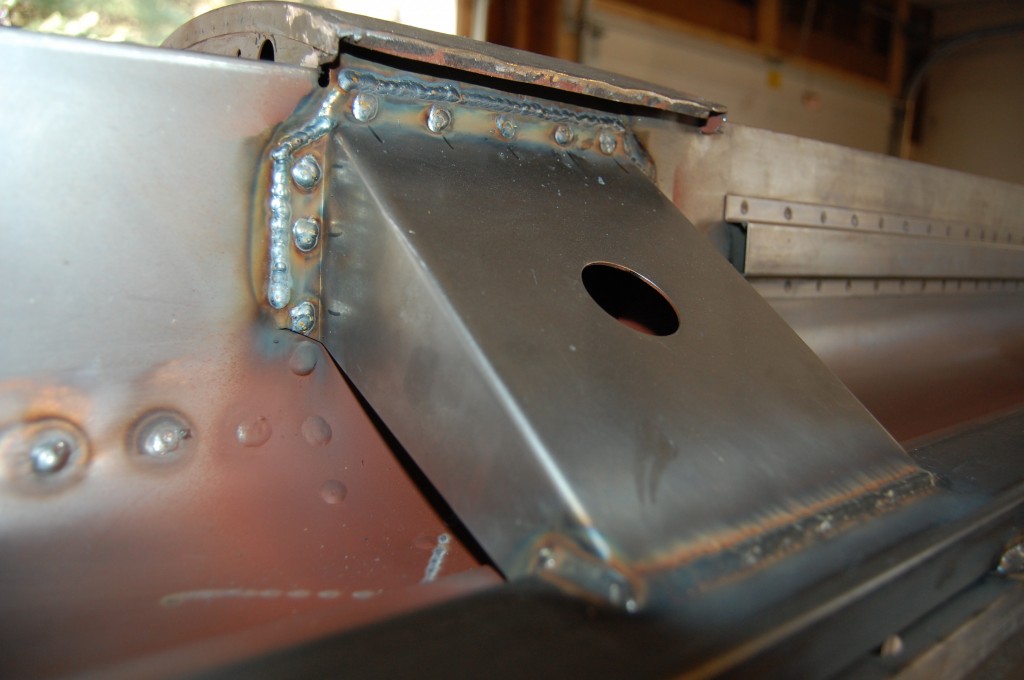

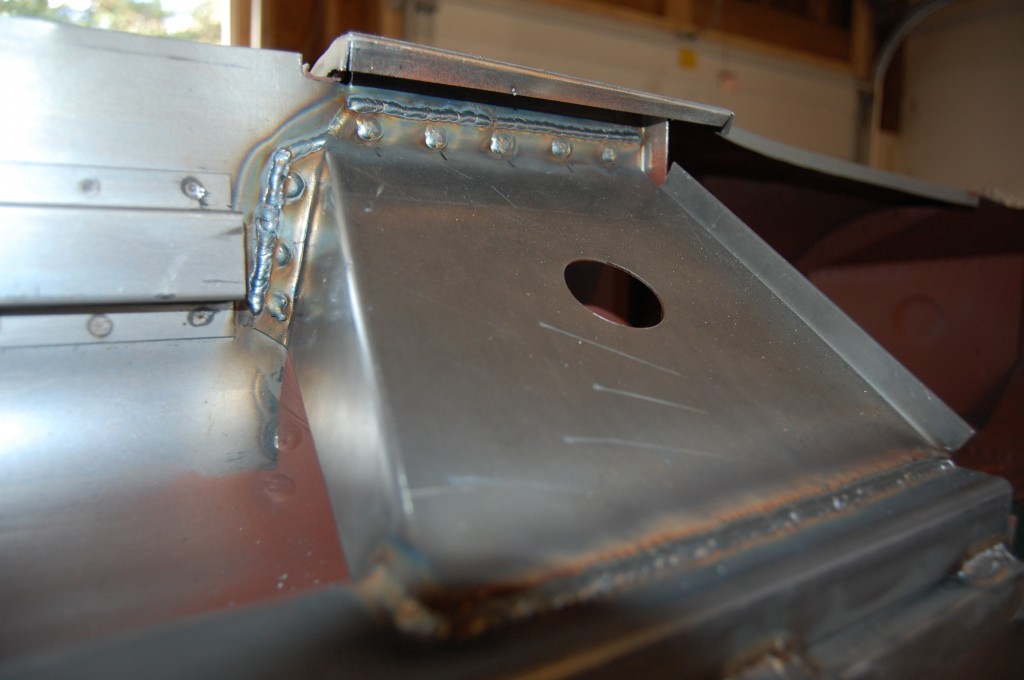

- After the rail itself is welded in, we add in some of our own gussets – formed from 16-gauge cold-rolled steel instead of the hopelessly thin stock units.

- On the subframe, we’re not bashful with the weld strength!

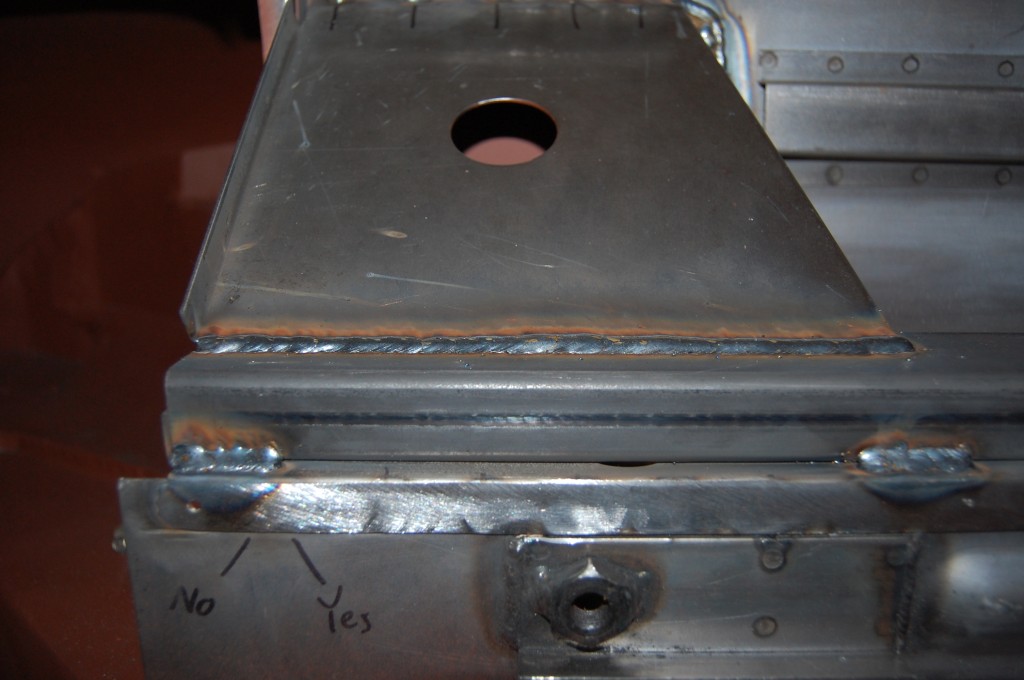

- Penetration and strength is our top priority in all welds.

- On the top side, we plug-weld AND run beads around the outer edge.

- Same goes for the rear gusset. Keep in mind that the inner sill is also uprated to 18-gauge from the factory’s 19-gauge.

- Other side before starting.

- Another shot.

- More beautiful and strong welds.

- There won’t be ANY more flex in the B-post when going over big bumps in the road!

- RH side completed.

- Red oxide is used liberally in all areas that will tough to reach later…

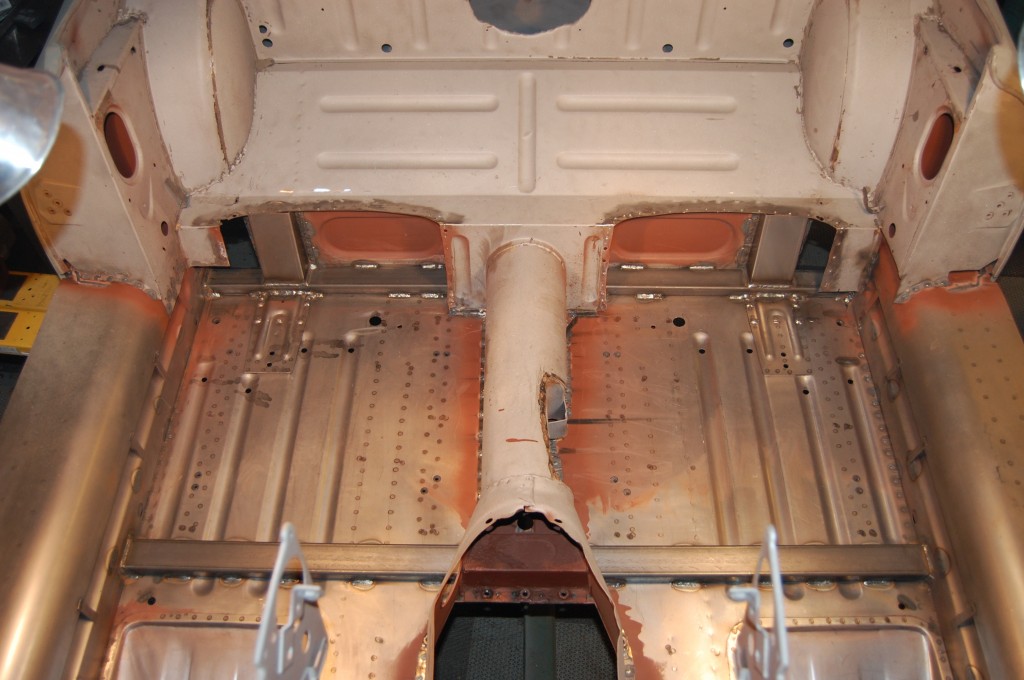

- Here is the inner rail that is hidden under the stock coss-member. In this shot, you can also see the full penetration of the welds from the sill rail. Note that the intersection of these rails is located directly over the jacking point.

- Here is another shot of the crossmember rail – it is one continuous piece that slides under the driveshaft tunnel.

- Another shot.

- One more shot of the crossmember rail. This should help – ALOT – in the case of a side impact.

- Here is a shot of a 16-gauge gusset being fitted in above the rear bulkhead rails. We ALWAYS get as much paint into the enclosed areas as possible.

- This is a good shot showing the rails inside the rear bulkhead. These also help with the side impact, and provide a rock-solid support for the radius arm cups. This is one E-Type floor that won’t be flexing under stress from the rear axle!

- Directly behind this vertical gusset is the rear chassis leg. This gusset is present on the stock shells, but inorporating this rail below it REALLY adds strength to this area.

- Here’s a shot of the other side.

- This shot shows the forward and rear cross rails of the subframe, and the welds from the side rails. This strengthens the shell SUBSTANTIALLY, and boxes in the cockpit nicely for safety. It is tied into the outer mounts of the front engine frames, intersects at the jacking point, and fukly supports the radius arm cups. We have this down to a science, and install it in almost every E-Type that gies through the shop. It adds minimal cost, really, and minimal weight – approx. 32 lbs. Ready to take your E-Type’s shell to where it shoube be? – give us a ring!