OK – So far all we’ve done is take a ’68 roadster shell and cut and grind it down into almost nothing! Time to start moving in the other direction! Here are a couple of photos of the first repairs on the shell, which will allow us to start fitting the floors and sills. This is the reconstruction of the forward ends of the rear chassis legs. Rust often gets into this area – it is a water and moisture trap.

- Remember this? This is bulging rust in the seam between the LH chassis leg and the rear lower bulkhead.

- We first removed the support behind the seat. Incidentally, the factory “forgot” to weld the whole inner seam of it – I actually see this alot on this piece for some reason…

- So we cut everything out until we were back to good, solid metal.

- Then went berserk inside the chassis leg with red oxide while we had the chance!

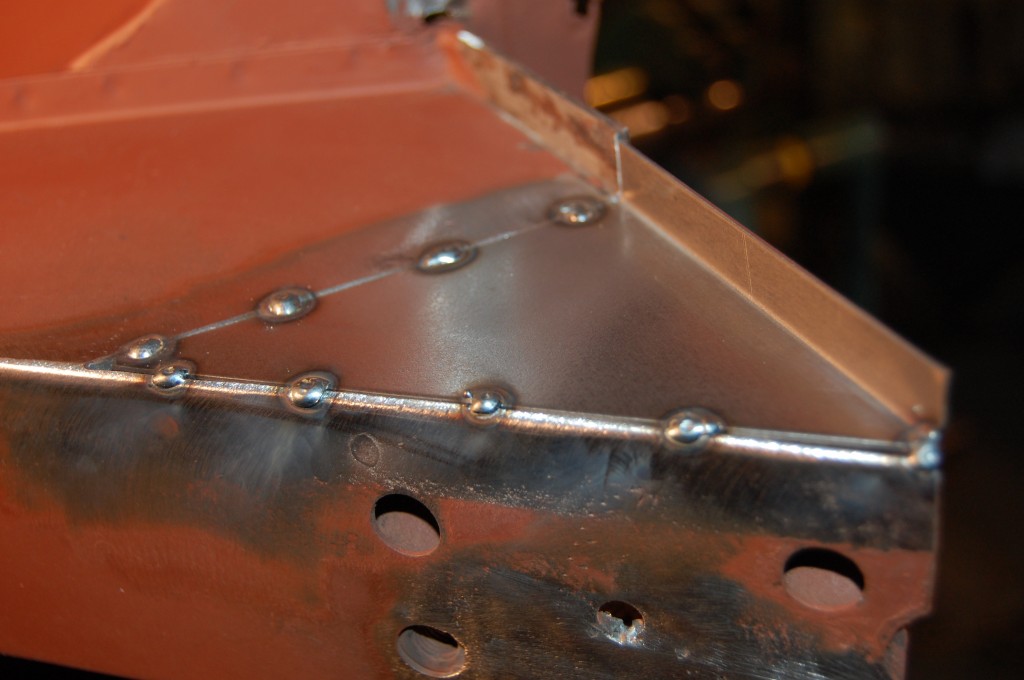

- Here is a shot after the repairs – we have welded in a patch to the rear bulkhead with 18-gauge cold-rolled steel, and also added back in the lower 1/2″ wide flange, which was messy and cut off during dissection. Once we have the subframe in this car, that flange will be irrelevant to the structure, but we need it to align the floors, and it will also seal things shut tightly.

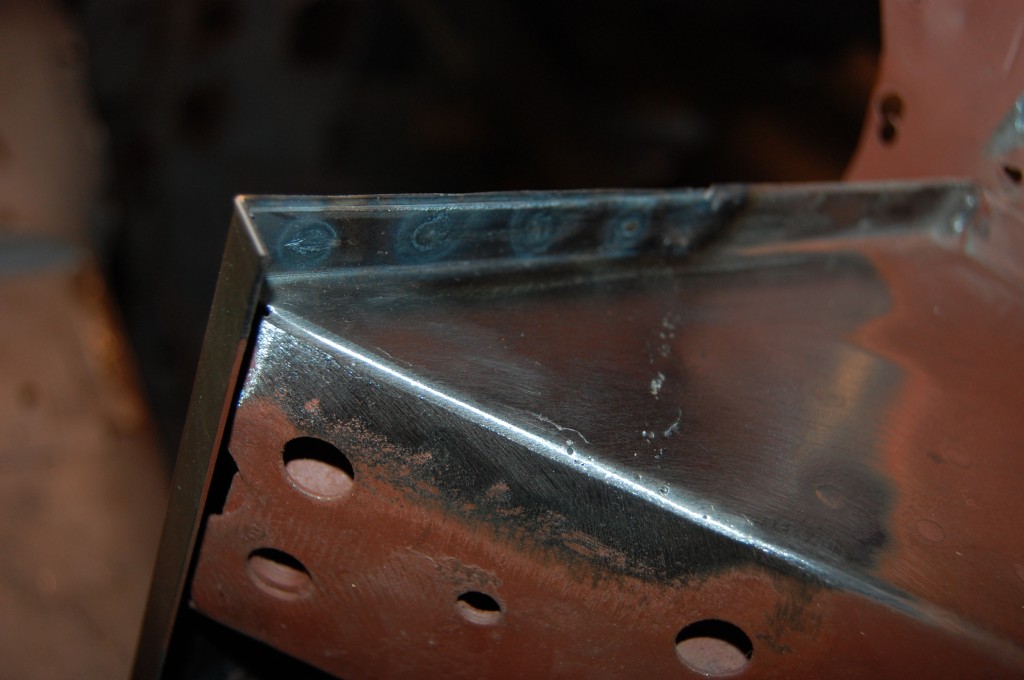

- A triabgulat patch was put into the outer edge of the chassis leg itself – also 18-gauge.

- Here’s a close-up. This area is back to how it should be, and we can move forward with positioning the LH floor now!

- We ended up cutting this back even further once we got into the rebuild. There are double layers of 18-gauge in this leg, and ANY bulging of that metal (meaning rust is developing in between…) needs to be completely cut out.

- We also ended up putting a small patch down in the midst of these holes – it was a pain, but it MUST be done completely, or the rust will just eventually get started up again.

- We also cut this triangular shape a little larger for the same reason. Here it is tacked into place. Next, we’ll fit the patch on the face panel, and do the final welding when it is all in the proper locations.

- Kust like the other side, we also had to replace the complete bottom flange on this side of the rear bulkhead.

- All welded up and ground smmoth, and coated with red oxide. Time to fit the floors!

- Before…

- …After.