Much of the metalwork we do is kind of a “black art”… It’s tough to figure out what to do, how to do it, and what tools are necessary. Then even AFTER you figure all of that out, it takes YEARS of practice to get some of these techniques down.

So… it’s really helpful to trade ideas with other guys who do the same work, and I recently had an opportunity to do that with a visit to Comstock Metal Shaping in Herkimer, NY. Each Summer, metalworkers from around the country get together very informally at Ducth Comstock’s shop to trade ideas and teach each other the in’s and out’s of metalworking.

I was only able to stop by for one afternoon, but was able to meet some great guys, learn a few things, and get ALOT of good ideas just from checking out the machines and tools within the shop. Here are some photos I took during the visit – this is a SERIOUS shop!

- Large, deep throat shrinker and stretcher.

- Monster English Wheel built by Kerry Pinkerton of Imperial Wheeling Machines. Kerry is well-known for making some of the best wheels in the country.

- Every nook and cranny of this shop was JAM-PACKED with metalworking tools!

- Ducth’s home-made planishing hammer – which was bigger, stronger, and better built than any I have evr seen.

- The design incorporated two lower arms on one frame for different approach angles providing the ultimate clearance for any piece.

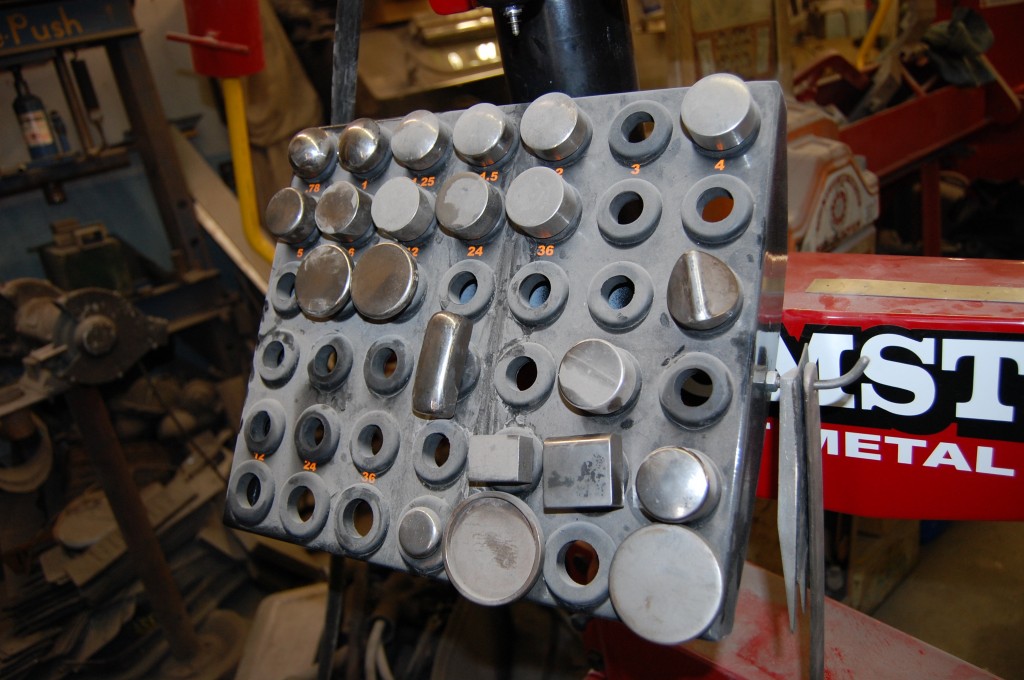

- Complete with LOTS of dies!

- This Dreis & Krump finger brake was the same basic design and vintage of our D&K Universal break. Many of the castings and components were identical.

- Every style, size, and shape of hammer was available.

- Here’s the OTHER side of that board!

- This is a pneumatic shrinker-stretcher – easily forming a frame rail over 1/8″ thick!

- Vice Grips – you can never have too many…

- This was a really great fender fixture – we have got to build one of these!

- We have a more basic version of this punch – a Diacro #2 with a 12-inch throat. This is a Diacro 18-place turret punch – I pine for one of these every time I change the dies in our 1-station punch!

- A “smaller” english wheel by Imperial.

- The MOTHER of all shaping tools – Dutch’s Yoder power hammer. After about a 60-second demonstration, I was deaf.

- Right next to it – their Pullmax reciprocating machine.

- Tooling for the Pullmax.

- More custom tooling for the Pullmax – this drawer represents YEARS of trial and error to replicate specialized beads and shapes in panels.

- I was in awe of the time that had been put into these pieces. I’ve been there myself, but not THIS many times!

- I used these tucking forks for a few hours to practice shaping a piece based on a flexible shape pattern.

- Specialized hammers for shrinking and stretching.