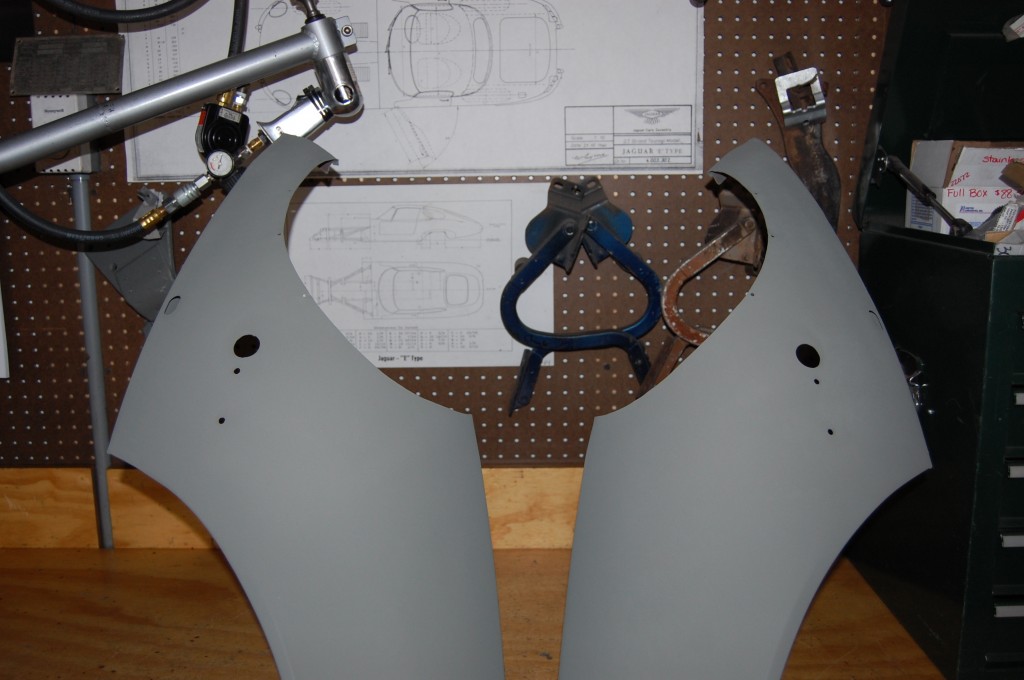

Next it was time to restore a pair of wings for this bonnet. These wings are a matched pair that we picked up last Fall. They have some issues, but overall, are straight, and the difficult to repair V-12 wheel flares are excellent.

- I did manage to grabe a couple shots of these with my phone before they went into the blast room.

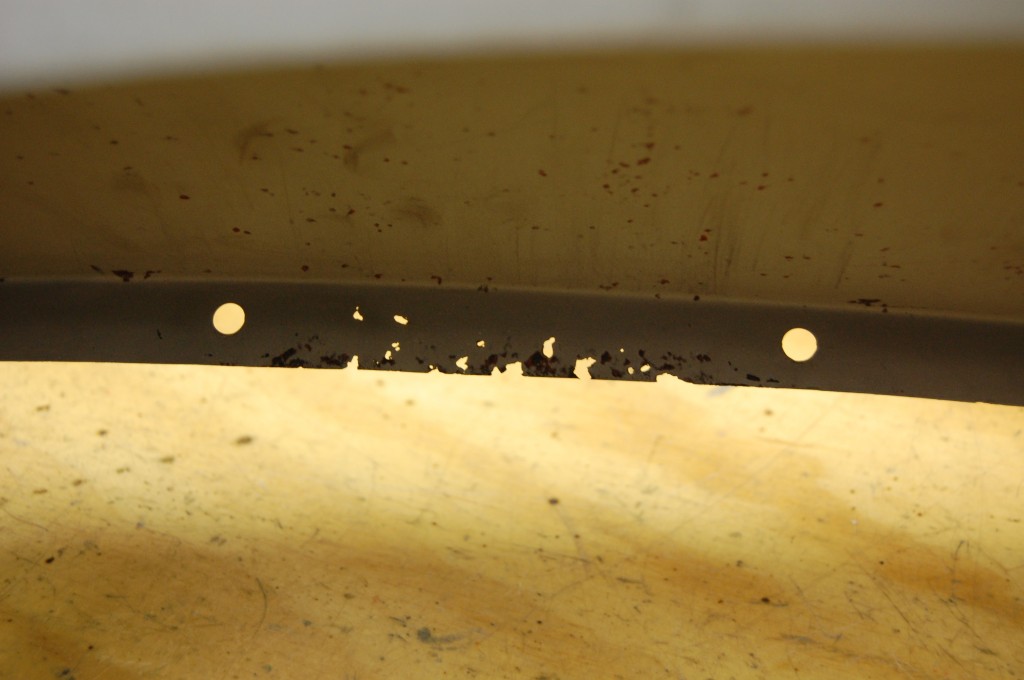

- Here is the underside.

- This area was pushed in around the forward bonded flange, and will need reshaping.

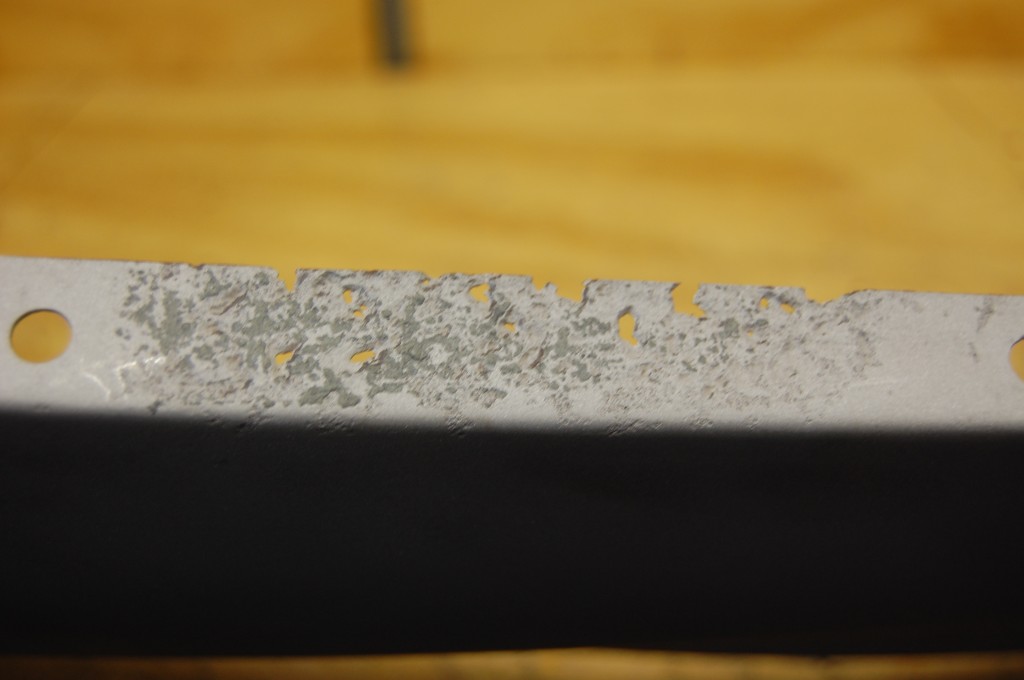

- Kinks and cancer in the lower rear corner of the LH wing.

- Some cancer in one of the side flanges will need to be cut out and repaired.

- Another shot of the heavy pitting that eventually caused that cancer.

- The issues in the lower rear of the LH wing have been remedied – a small patch has been welded in and sanded smooth.

- Here are the completed repairs to the side flange.

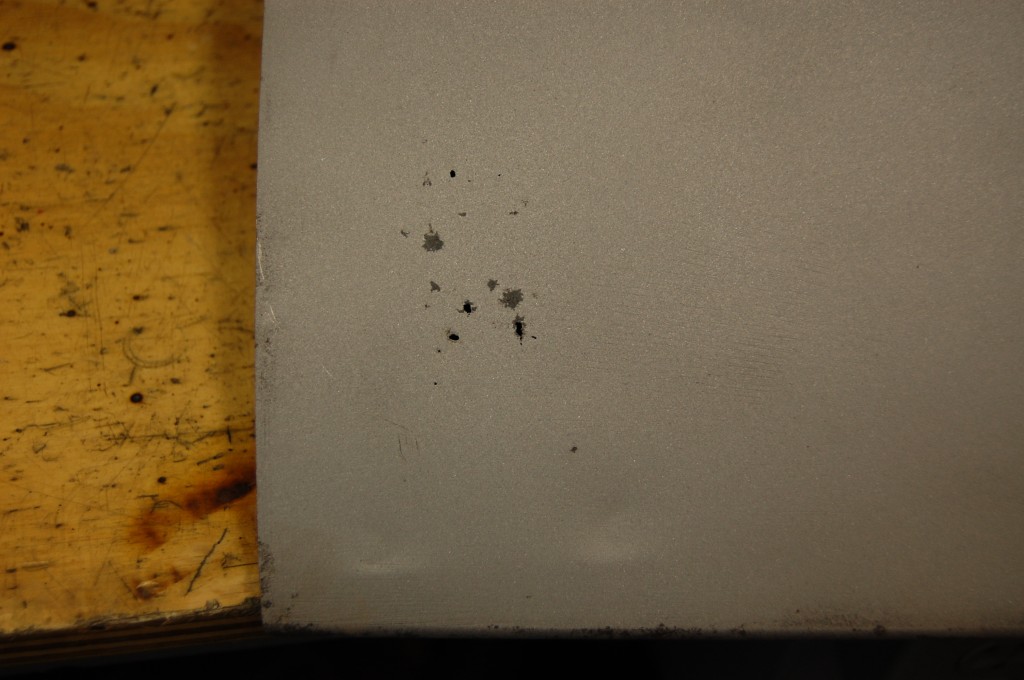

- Cancer under the rear support is worse on the RH wing.

- And MUCH worse at the top corner. This will need major surgery.

- Rust in the middle RH wing flange is also bad – this will have to come out.

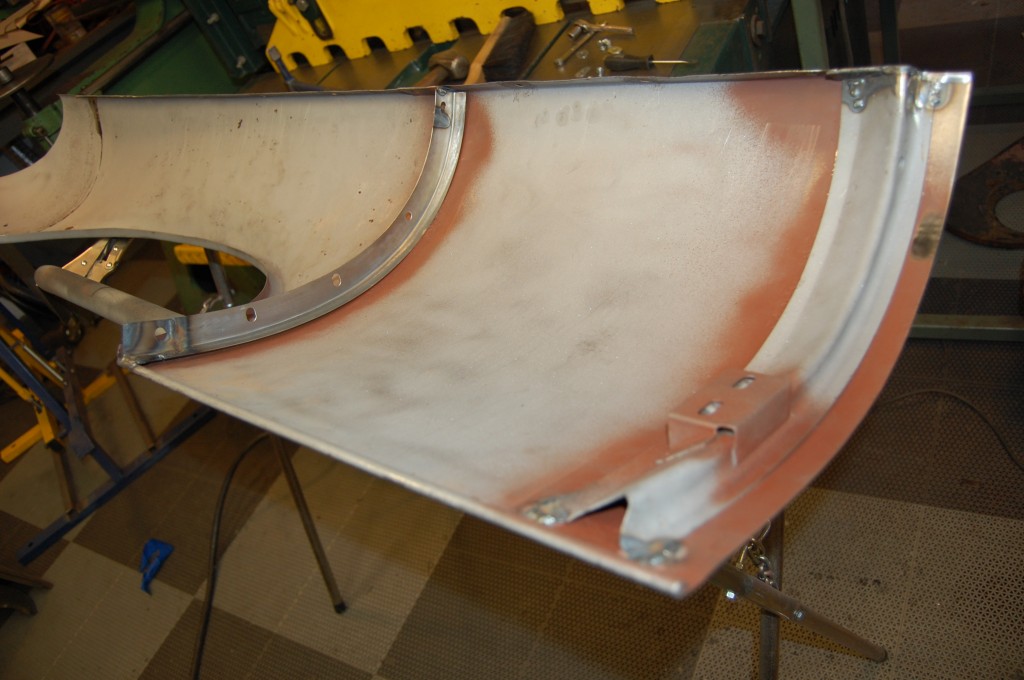

- The middle bonded flange and the rear support have been removed, and cancerous areas of the skin have been cut out for replacement with new cold-rolled steel.

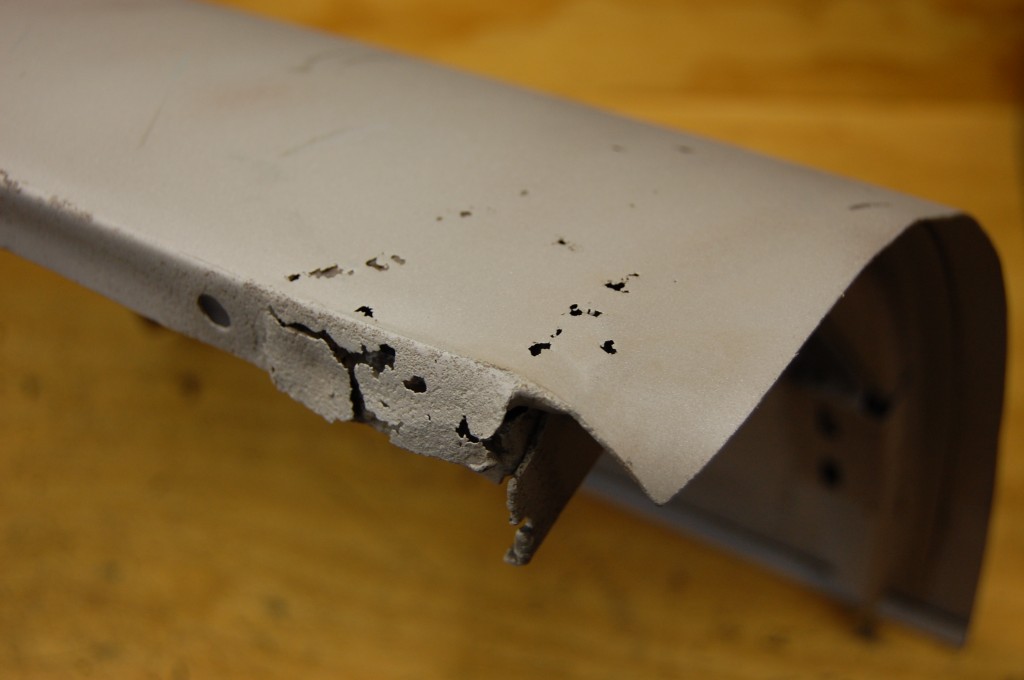

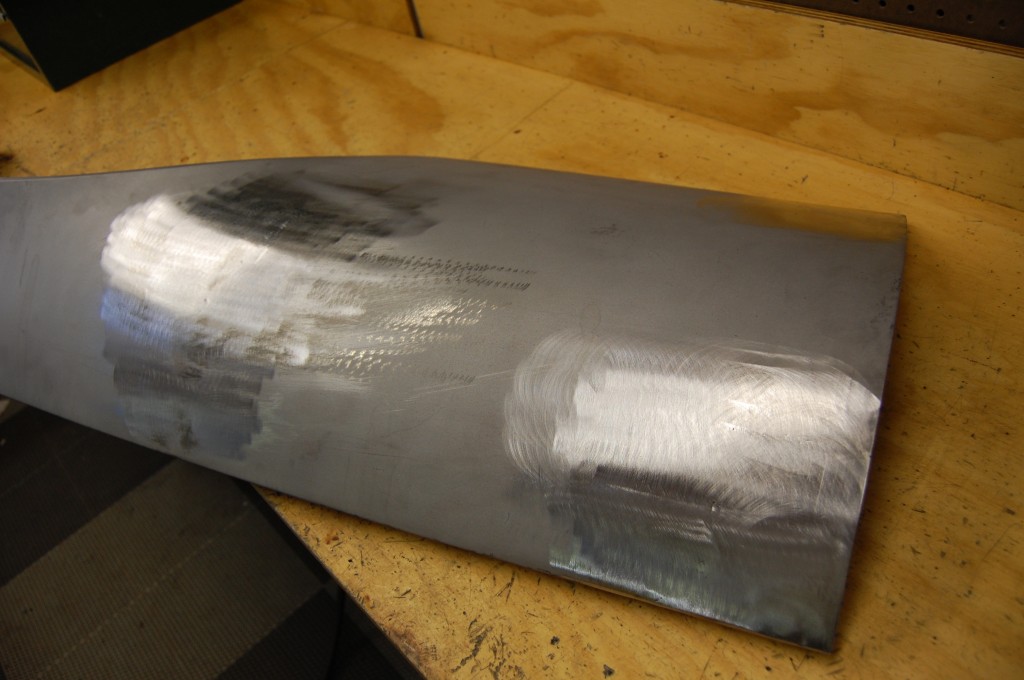

- Here, the patch has been welded into the lower corner, and shrinkage in the welds have warped the wing. Proper stretching and smoothing of the metal in this area will need to be done now. This is where a repair like this goes off the rails for the home restorer or inexperienced shops – they don’t know what causes this, OR how to reverse it, and so they whack away at it for a while and then just fill it with bondo. OR – tell the customer “we tried, but it was too far gone, and you need a new wing (for $1400 that doesn’t want to play nicely with the rest of your bonnet…)

- What needs to be done here is proper planishing, so that all shrink caused by the welding is removed, and no additional stretch beyond that is introduced in the process… The two holes are where the spot welds for the inner support were drilled out. These will be used to plug-weld that support back into place.

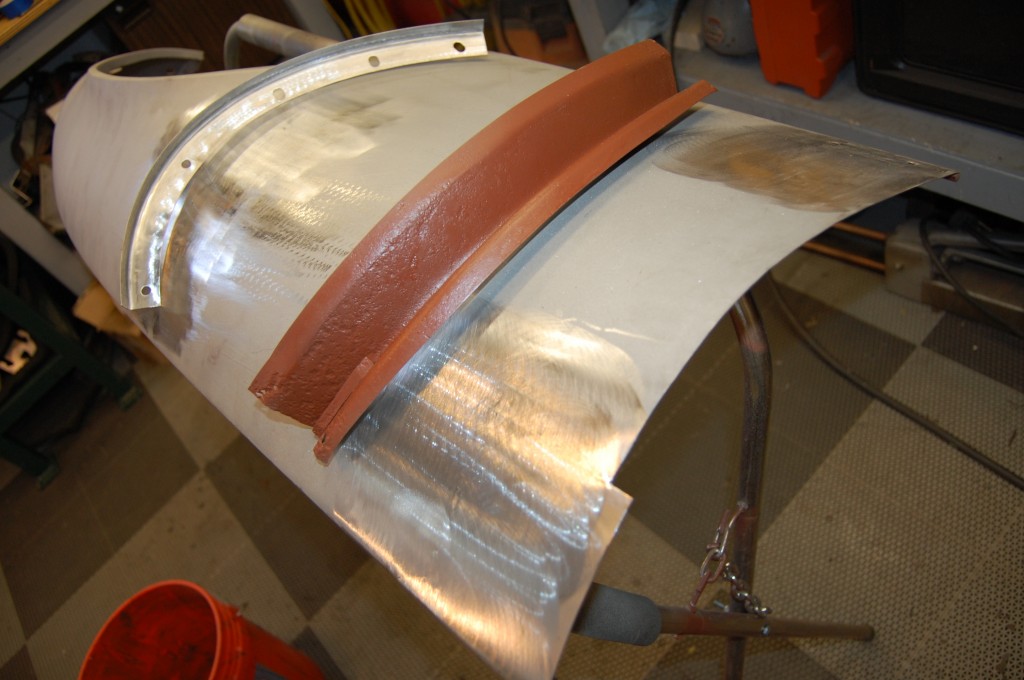

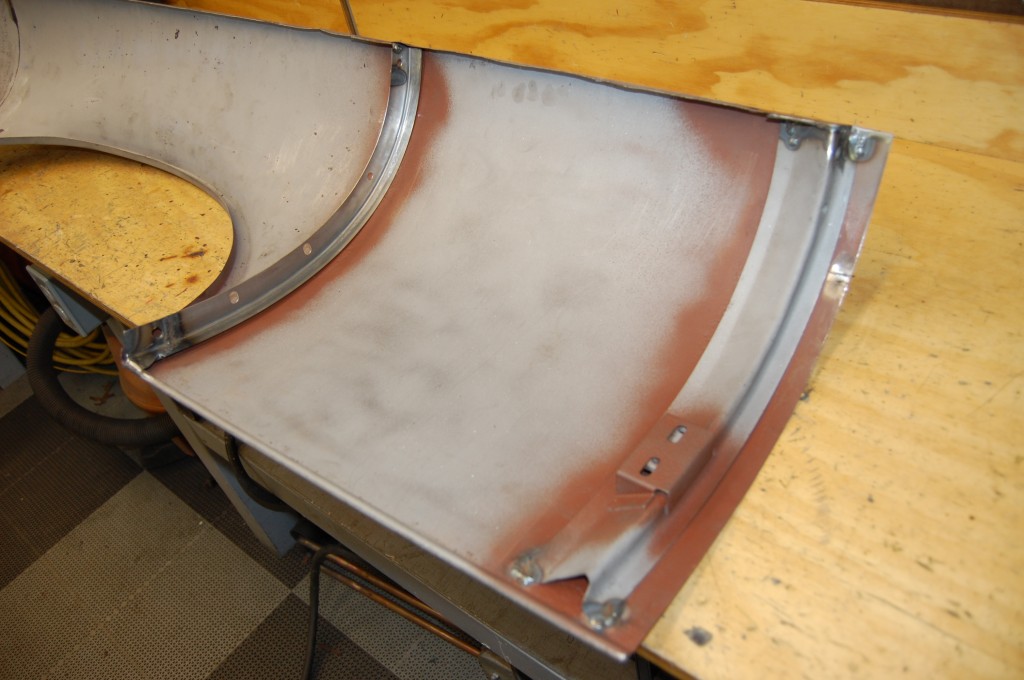

- Now, all three areas have been cut out, new steel welded in, the welds finished, and the areas planished. A new middle bonded flange has ben fabricated, and the rear support has been plasted bare and primed with red oxide.

- Next, the supports are welded in at the ends, and the middle support will be filled with bonding agent in the final bonding step of this bonnet build.

- A messy E-Type V-12 wing brough back from the dead!

- The repair in the top corner has been trimmed to match the rest of the rear edge of this wing – which is nice and long. Sometimes, used wings and center sections have been trimmed multiple times and are very short – these are still at their virgin, factory length.

- All issues – dents or rust – have been resolved. These fenders are as good as new, and a simple coating of block-sanded, high-build primer will cover the repairs completely – no filler whatsoever will be necessary here.

- Dents and minor accident damage in these areas have been reshaped, smoothed, and essentially erased.

- And the V-12 wheel flares are perfect!