The next order of business for this shell is to close in the box sections where we have hidden the subframe rails, and also replace the crusty driveshaft tunnel and transmission sides with new pieces formed in our fabrication shop.

- First we close up the seat recesses in the lower rear bulkhead. There is just enough room in this section to lay in the subframe rail. The next car up is also a coupe that will be getting a hidden subframe as well – a ’66. That car is owned by a taller customer, and we intend to stand these pieces on edge, then dish the recess in much deeper to add legroom by moving the seat back further than stock.

- The original tunnel has served its purpose for support and alignment while the floors were installed, and it will now serve one more task – it is an excellent pattern for new 3.8 trasmission sides.

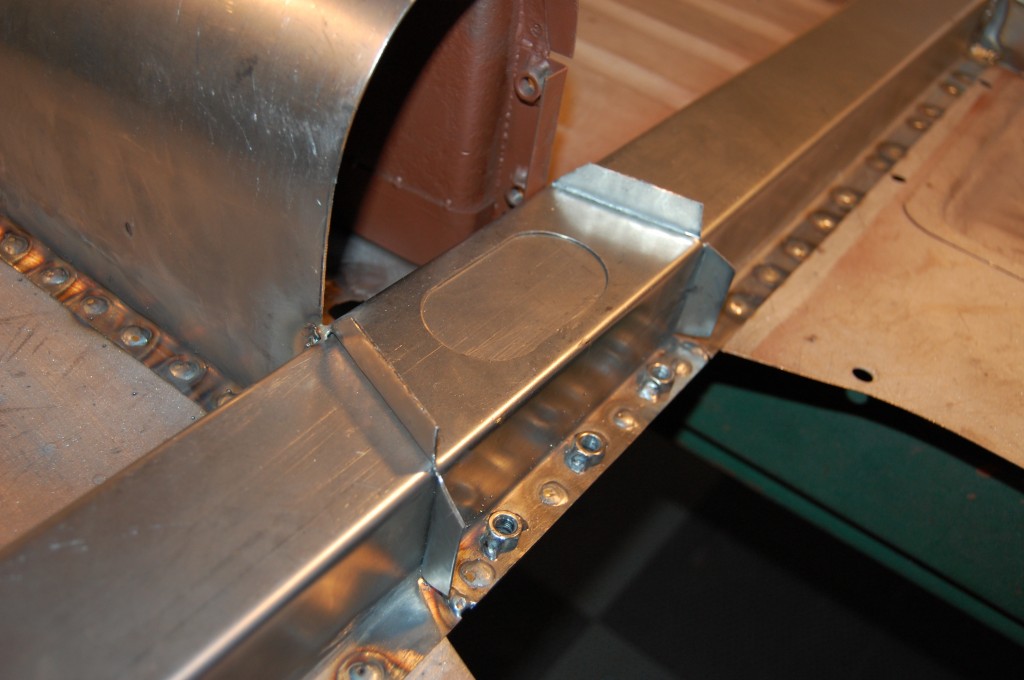

- This is the additional support for the rear transmission mount – it is an extra layer that wraps around the crossmember, inside the tunnel. It also serves to locate that transmission tunnel sides. The oval in the center is pointless, but I end up putting it in everytime because it just looks so cool – and is correct!

- Talk about additional side-to-side strength – this is an upgraded 18-gauge crossmember, welded over a piece of rectangular steel tubing! Nothing short of a freight train is going to collapse THIS E-Type’s cockpit!

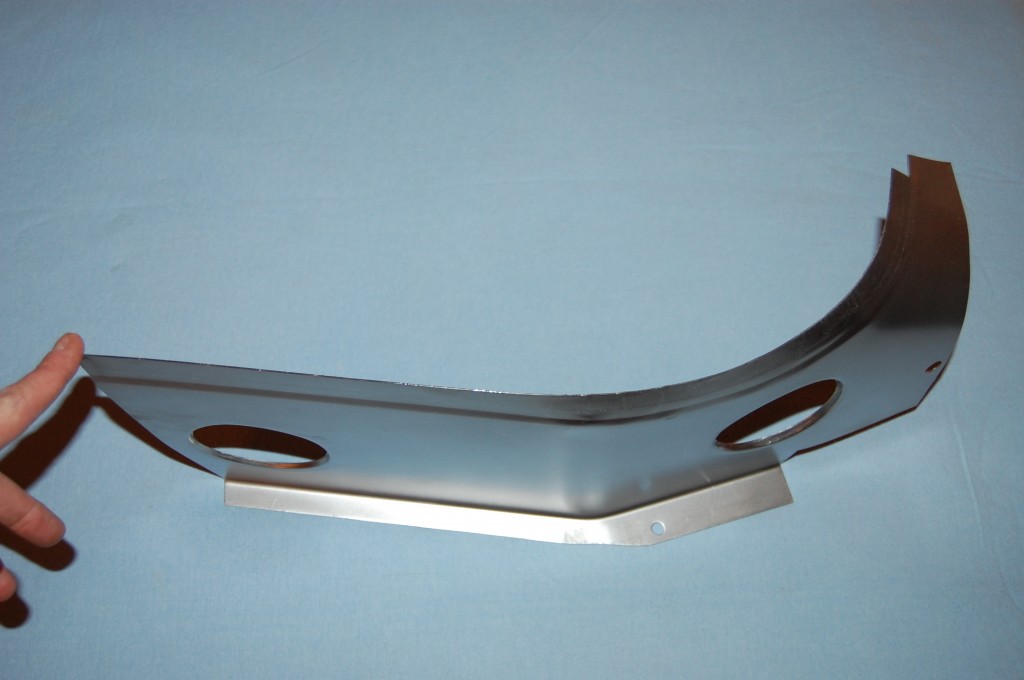

- Here is the new RH Transmission tunnel side for a 3.8 – we took the extra time during this project to finally tool up for the manufacturing of these panels, and have them available new for 3.8 and 4.2 cars.

- This is the new LH panel. These are notorious for fitment issues – and especially known for having holes of the wrong size, in the wrong locations. Ours are EXACT – we patterend them after all 8 E-Type shells in the shop currently!

- Top view of the LH side. The forward hole is for the transmission oil fill, the rear is for access to the speedometer cable angle drive.

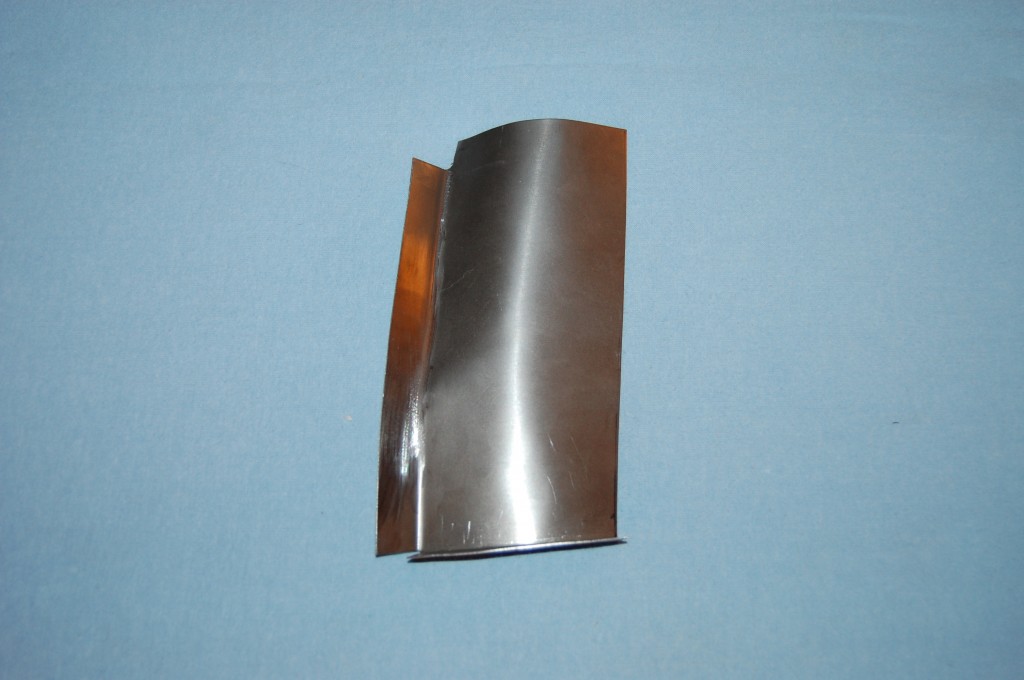

- Don’t forget “the wedge”! This panel drives me crazy! It is like some type of factory flaw – we’re not really sure WHAT it’s for! It’s small, but hard to make, and even harder to fit into place…

- Here is the pair of 3.8 transmission sides, ready for installation. Don’t buy from “the other guys” and then fight these into place – call us for panels that fit perfect.

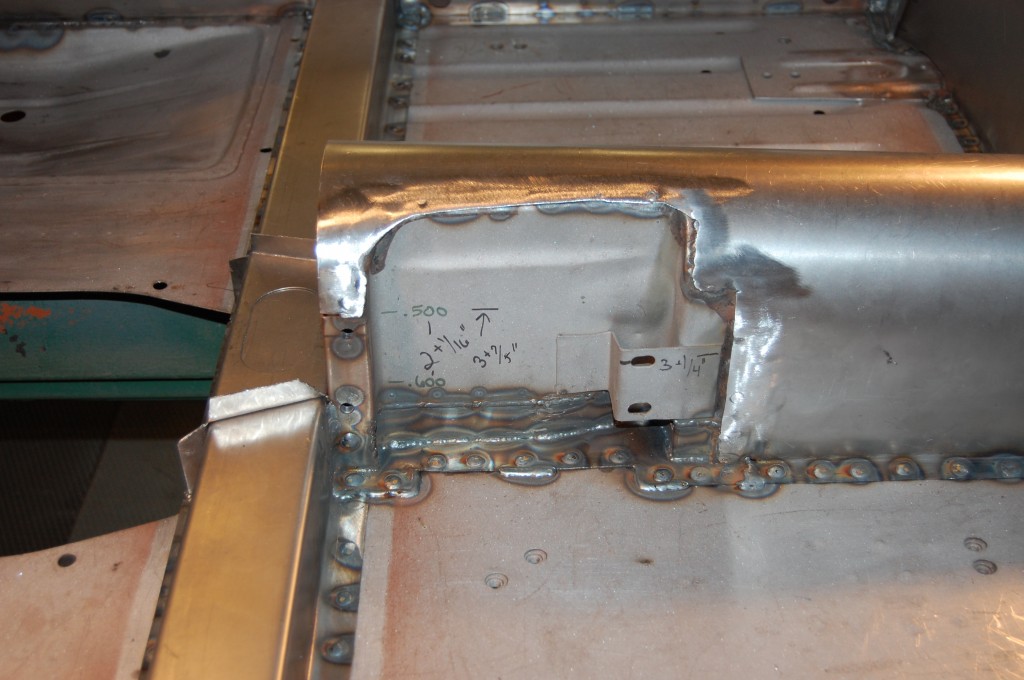

- When we have to make a new tunnel, we usually try to save the handbrake recess. It is a stamping, and VERY time-consuming to make from scratch – and tricky too! Here, we have addedabout an inch of new 18-gauge metal to the bottem, and welded it into a new 18-gauge tunnel we formed up. This is the inside of the tunnel, liberally coated in red oxide, as usual…

- Here is the outside, showing measurements for the proper height and location of the forward handbrake mounting holes.

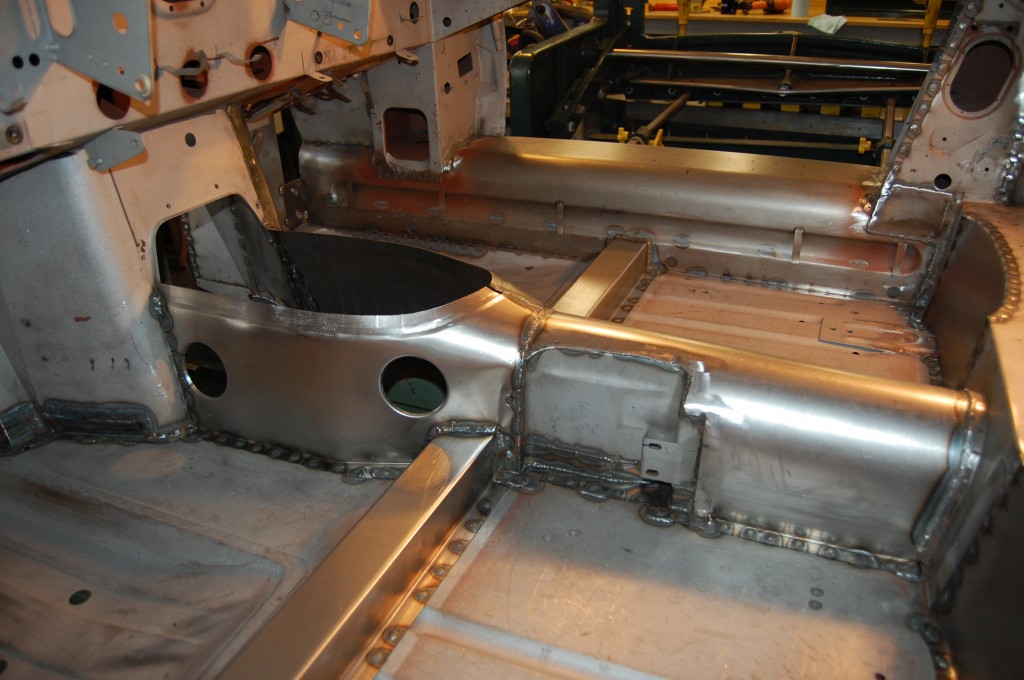

- Here’s the new tunnel welded into place. The tunnel actually goes all the way back to the rear of the box section at the lower edge of the rear bulkhead. but we have welded this new one in right at the forward seam. The weld is strong, and this is an acceptable compromise.

- New we have the new tunnel in place, and you can see the seat recesses in this shot as well.

- The proper size nuts have been welded in the proper locations for the rear trans mount.

- Other side…

- The crossmember is originally spot-welded to the inner sill wil small tabs – it is a weak connection… When we make new crossmembers from 18-gauge, we weld them directly to the sill for added strength.

- Things got a little busy after the last shot, so we’re skipping to this – DONE! The transmission sides have been welded into place after a great deal of fitting to ensure that the tunnel cover fits properly, etc. Note the location of “the wedge” – it always looks like a patch, but it’s factory correct on every SWB E-Type.

- Another shot, looking rearward.

- Driver’s side. Everything is located properly, is correct, and rock solid!

- We did patch the lower inch or so of these panels. On a car this rusty, you have to stop somewhere, and we elected to leave these in place with a strong patch in the very bottom.

- LOTS of welding in this job…

- Now that’s MUCH better! Go back a few blog entries on this project, and you won’t believe it’s the same car!

- With almost every panel in this photo uprated to 18-gauge, and the hidden subframe as well, this could be the strongest E-Type cockpit out there – but just as we planned, it looks BONE STOCK!!!