These doors are being built for a customer in Australia for a 1965 E-Type Fixed-Head Coupe. I LOVE dealing with guys from Australia – they always seem SUPER happy! And phone rates down there must be very reasonable, because I’ve had several Australian E-Type owners call me to ask about parts! – ‘Ello, Chuck! I’m calling from Melbourne, Australia – how are ya’ mate!?! – that never gets old – I love those guys! It’s also cool because they are pretty much exactly right on the other side of the world, and their time zone seems to be exactly 12 hours ahead of mine. So I’m always asking them if it’s light or dark out because it’s the opposite of what it is here and the conversation sounds like they are calling from down the street! But they’re actually calling from “the future” – and that’s cool too…

I’m not sure if the gentleman who ordered these doors actually had doors of his own that were in poor condition – we never really got into that and it wouldn’t matter anyway – shipping the cores over here would not have made sense – the shipping is pricey. So we just dug a decent matched pair out of our semi-organized mountain of door shell cores, and went to work building a brand new set of doors for him.

One other thing about Australian E-Types – I’m not sure if they are “supposed” to be right-hand or left-hand drive, but the customers who contact me seem to have an even mix of RHD and LHD cars. I guess they didn’t send too many E-Types down there in the first place, and the ones that have been brought in later as collector cars come from all over the place – mostly the States I would assume.

One last thing is that In Australia – and most other countries besides the US it seems – used E-Types parts are REALLY tough to find! And when I have mentioned to a couple of these guys that I have been to more than one place where there are dozens of E-Type parts cars under one roof, it just blows their mind!

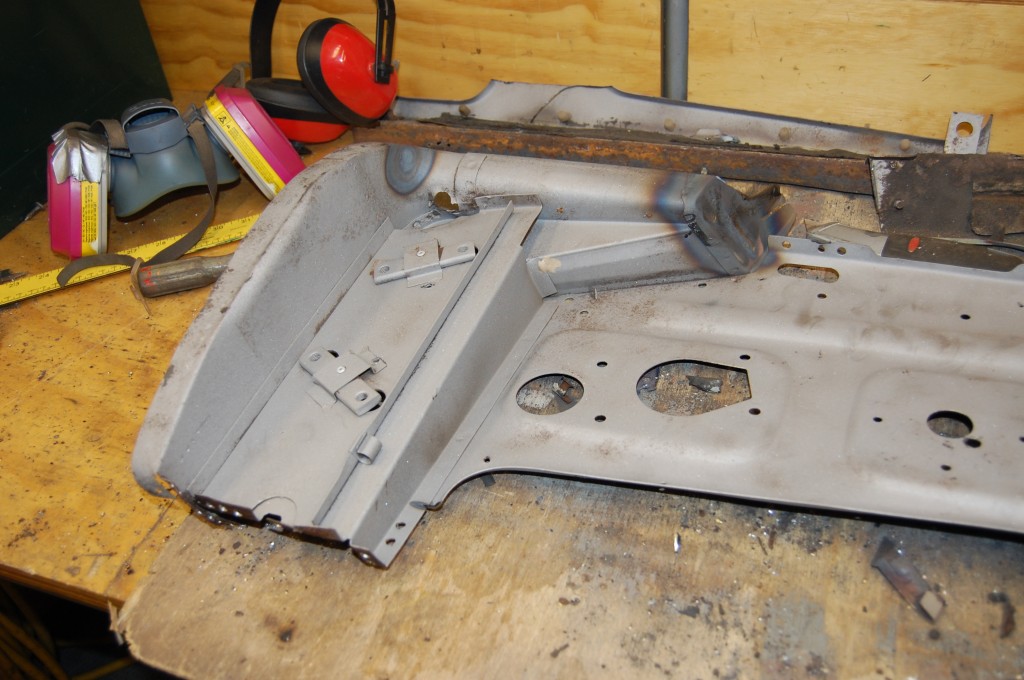

- Here are the donor shells – I’m pretty sure they are from the same car, although they have some different paint on the outside – and some dirt and grime too…

- Here is the inside – which is all we are concerned about anyway on a donor. Even if these weren’t from the same car, they were an almost identical match. Doors are not all the same – there are very slight differences here and there and when we build a pair, we make sure all of that stuff is the same. Note that these are “4.2 doors” – they do have the armrest mounting points.

- The drip trays were the wrong style, but we always pull them anyway. These doors had the late “curved” drip trays, we needed the earlier “dogleg” style for these doors.

- Dissecting doors is a mess… These shells are excellent donors – the hing support area is rock solid.

- We blast the shells bare inside and out, and after the new bottoms are grafted in, we go nuts on the inside with red oxide.

- Now we’re done with most of the mess, or at least the rusty and jagged metal. We always cut the doors in the same place for the bottom patch, and it leaves a sharp point on that long oval hole, and I have taken that point in the soft parts of my body on more than one occasion – AAGGGHHHH!

- After the drip trays are out, we glass bead the area so it can be well sealed.

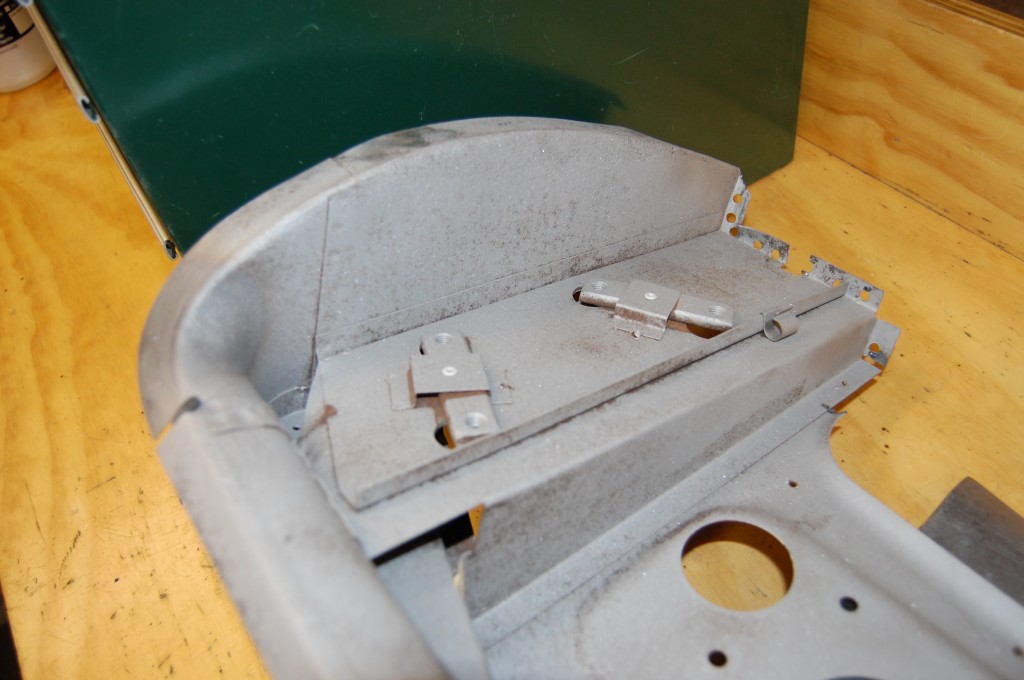

- Here is the other side…

- Another shot of very solid hinge supports.

- Imperfections in the aftermarket doors skins – you’d be surprised what gets hidden under that crummy black primer…

- The other side had the same little repairs – I assume these might split here when they are pressed.

- A dent NOT put in here, OR in shipping – these were well packed and this was inside the other door. SO – the supplier packed these with this dent in it, and furthermore, the primer did not have a mark on it – I think this dent was on there before these were even primed at the factory. It’s minor, but nice quality control, guys… We took it out, of course.

- Another shot of post-production repairs at the aftermarket factory. Door skins are pressed, and the shape needs to be right, so we buy them. But every time I skin one, I keep looking at all of the little imperfections, and I’m just about ready to have a go at them here…

- I thought I too photos of the completed shells in primer but I guess I forgot. These have now had the lower sections repaired, and the skins have been spot-welded in a few places to hold it in place while the edge is turned. This is EXACTLY how it was done bu Jaguar originally – we even put the spot-welds in the same place.

- Another shot showing the precision of the lower patch. We seam the piece where we do so that it is covered by the interior door panel – even though the seam is nearly flawless anyway. That way, when you open the door and look at the painted bottom, it’s perfect.

- Red oxide will protect the area under the drip tray from rust coming back. Originally, they put a piece of sticky, tar-paper-like stuff between the drip tray and the door shell as a gasket. I’m not sure why, because if it “leaks”, the water just goes into the bottom of the door where it all goes anyway! If it was to prevent rust, that didn’t work either, so we do not do that here – we just coat the door shell and the drip tray with quality modern paints instead. Stay tuned for the completeion of these Aussie doors!

- I KNEW I took a picture of these just in primer before the skins were attached – it was on my phone. Like I said, once the bottom of the inner shell is repaired, we aren’t bashfull with the red oxide. Like everything else on an E-Type, at the factory, these were built in bare steel and then sprayed – hardly ANY paint made it to the inner surface of the inner shell, and there can be really bad rust in there. We like to make sure that our rebuilt doors will last a lifetime!