Recently one of the shops I work with installed a Colotti 5-speed into an E-Type. It was a kit from one of the larger suppliers, billed as “bolt-in”…

However, the restoration came to a grinding halt when they went to install the interior and test drive the car – the driveshaft was rubbing the tunnel where the handbrake recess is, and there was NO WAY the shift linkage would fit under the trans tunnel cover and console. So up she came to our shop for some “adjustments”…

- Here is how she arrived. Once you know the tunnel has to be modified, you can do pretty much what you want with it, and so this was peeled back to see what was going on and to stop the rubbing every time the car was moved.

- Here’s a close-up. Many E-Types with engine or trans swaps – or both, run into clearance problems in this very tight section of the tunnel.

- This is the shift linkage that came with the 5-speed kit. It seems very stout at first, but it had two issues – it didn’t fit, and the forward brace would bend on every shift making it tough to get all the way into gear.

- Here is as far as the trans cover would go down – not even close…

- This shot shows the driveshaft in there – the new trans is longer and so it pushes the u-joint yokes back – THAT is the problem. This shows the forward yoke on the side, but the real clearance issue came into play when the driveshaft turned 1/4 turn and the rear yoke needed LOTS more clearance.

- But you can’t go nuts, because the handbrake still needs to move throughout its entire range. So we’re looking at what we can do with everything in place.

- Top shot.

- Here is the trans with the shift linkage removed. That is one of the forward gears – the shift rod goes way in there!

- At first we cut this window in the hopes of building a simple bump, but there was no way – the upholstered console hugs this cover very close and would have needed the same bump – not an option… You can see our new linkage in this shot – we even tapered the rear collar for extra clearance – it’s TIGHT in there!

- In this shot, the new shift linkage is fabricated and installed, and as you can see, no clears the transmission cover. I didn’t end up taking any photos, but we also shaped and welded in a cover for this little window cut into the cover – it also curved upwards to add clearance, but only about 3/16″, becuase that is all the room there is between it and the metal console cover!

- Here is what we came up with on the shift linkage. The bars on the sides have been added to stop the rear mounting plate from wiggling back and forth during shifts, and it did!

- I know this looks like a crazy person built it, but trust me, this is the ONLY way this was going to work! And if so much as a 1/16″ of metal is added to this linkage – ANYWHERE – it will hit something!

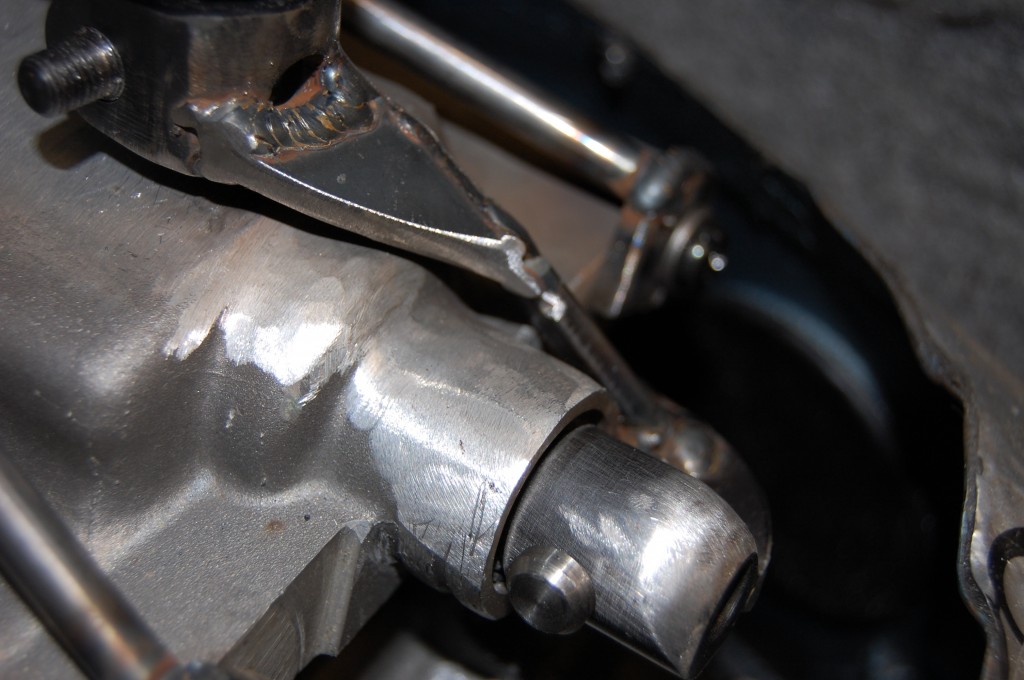

- We had to hug the transmission housing itself so close that we sanded off the casting mounts for the little bit of extra clearance that gave. Even the rounding off of the rear shift rod collar was necessary for clearance with the transmission cover.

- So in the end – weird looking, but it worked PERFECTLY! A couple months have passed now and the other shop has reported that the rest of the interior trim went back together as it should in stock form, and the car shifts beautifully. Another “snagged restoration” saved by Monocoque Metalworks. 🙂

- Here is a shot of the handbrake being fitted against the reshaped driveshaft tunnel. Clearance in here is CLOSE – you have to make sure the driveshaft U-joint knuckle has plenty of room to spin, but that the handbrake can still fit and operate in it’s full range of travel. There is no room for error here, and truth be told, we ended up doing this twice – the first attempt just didn’t have enough driveshaft clearance for my liking…

- Here’s a close-up of the driveshaft tunnel changes.