I don’t know what these things are actually called… This is another one of those panels that needs so much “re-work” usually, that I just started making them custom to each car.

This area traps dust, dirt, mouse nests, and then moisture that rusts out the lower edge – or the whole thing. It is a small panel, but tricky since it ties into important seams on all 4 sides, and is a compound curve.

- Ouch.

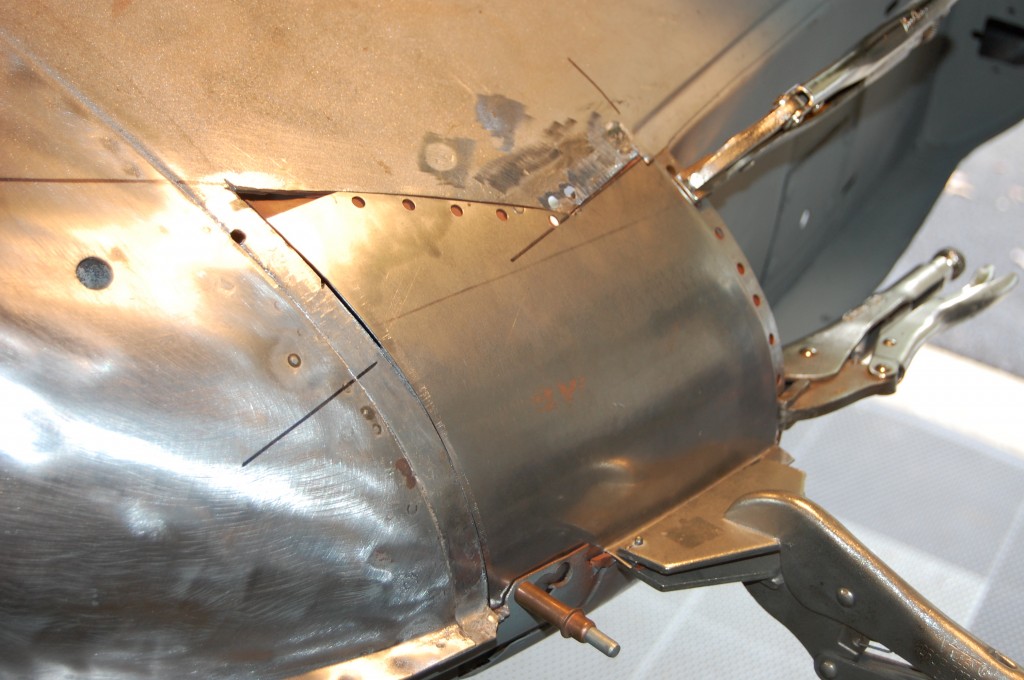

- Dissected and prepped. Note the inner panel flange – you need to pick that up somehow when welding in the new patch.

- Patch being formed.

- Initial fitting – note holes for plug-weldiong the patch to the inner support.

- More fitting – woops – misjudged things a little and had to weld on a small piece to make the patch fit…

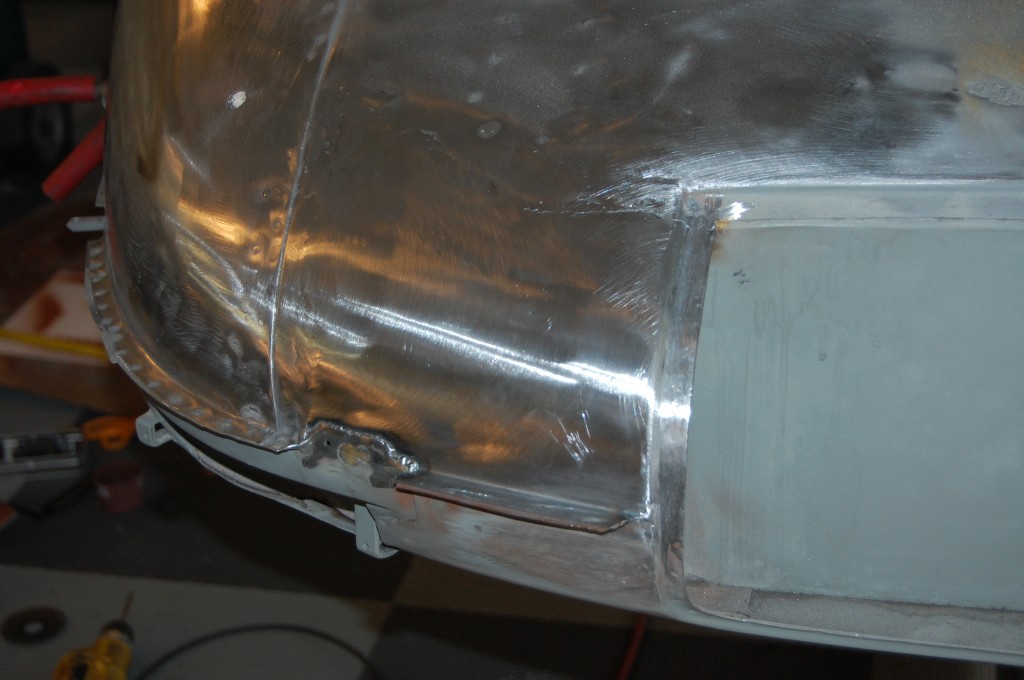

- The finished RH side – the car is upside down in the rotisserie.

- Another angle.

- Roughing in the LH side.

- Another angle.

- Don’t forget the red oxide!

- And remember to put it on the backside of the patch too!

- Another shot of the patch.

- The completed LH side.

- Success!