This post details the restoration of a pair of doors from a late ’61 (possibly early ’62…) roadster. The doors on the early cars have several subtle differences that set them apart from the average Series 1 door, and we’ll restore these doors properly – keeping all of those features intact.

These doors belong to a car on the very edge of transition from flat floors to the later floors with the dished footwell. We know this because the car was originally built WITH footwells, but WITHOUT the dished rear lower bulkhead for moving the seat back further – an interesting combination, and so I guess we know which improvement came first – if only on one car!

I grew up in a later 3.8 roadster with footwells, and always had my seat all the way back – and I’m only 5’-9”! I had two friends about 6’-2”, and both of them found it very tough to drive the car, actually. Recently, I have been sorting out the ’61 roadster for sale on my website, and from the very first drive, it felt weird… First, I just was dying to get the seat back a few inches! The foot placement didn’t seem too strange at first, but after about 15 minutes, my leg started to cramp up! I guess I’ve gotten used to that because that went away, but I can see why they went with these two changes early in the production of E-Types, and I’m all for it!

Anyway, back to the doors… The car is currently in Texas, but it must be one of the damper areas of Texas, because they are very rusty. Just about every door that comes through the shop now needs both a new skin and a new lower section of the inner shell. These doors were also badly rusted in the forward, upper portion that forms a drip tray about 8” long below the windshield pillar. This usually happens when the drip tray drain tube gets plugged up and water sits in there. Ironically, these early doors have not one, but TWO EXTRA DRAIN HOLES from the factory, and they’re some of the rustiest I’ve seen yet up there!

Take a look through the photos to see some of the special features of these early doors, and our correct restoration of them back to 1961 specs:

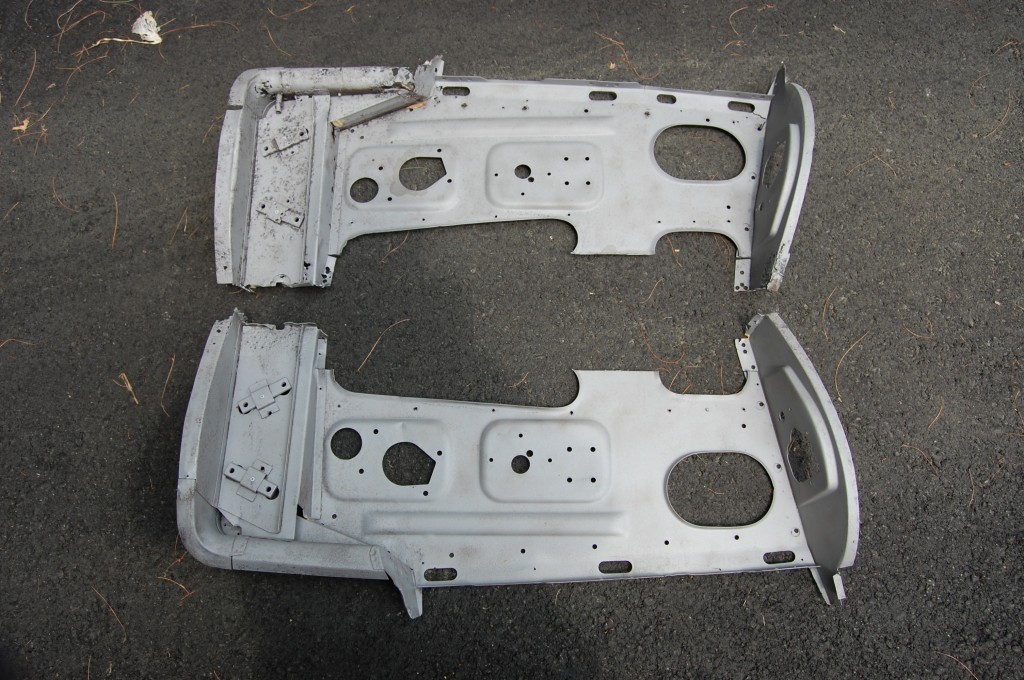

- Here’s our starting point – original 1961 doors are white, on the bottom – middle row is the coupe skins we will use to build the new doors – upper doors are a 3.8 RH and 4.2 LH donor since the originals are so heavily rusted…

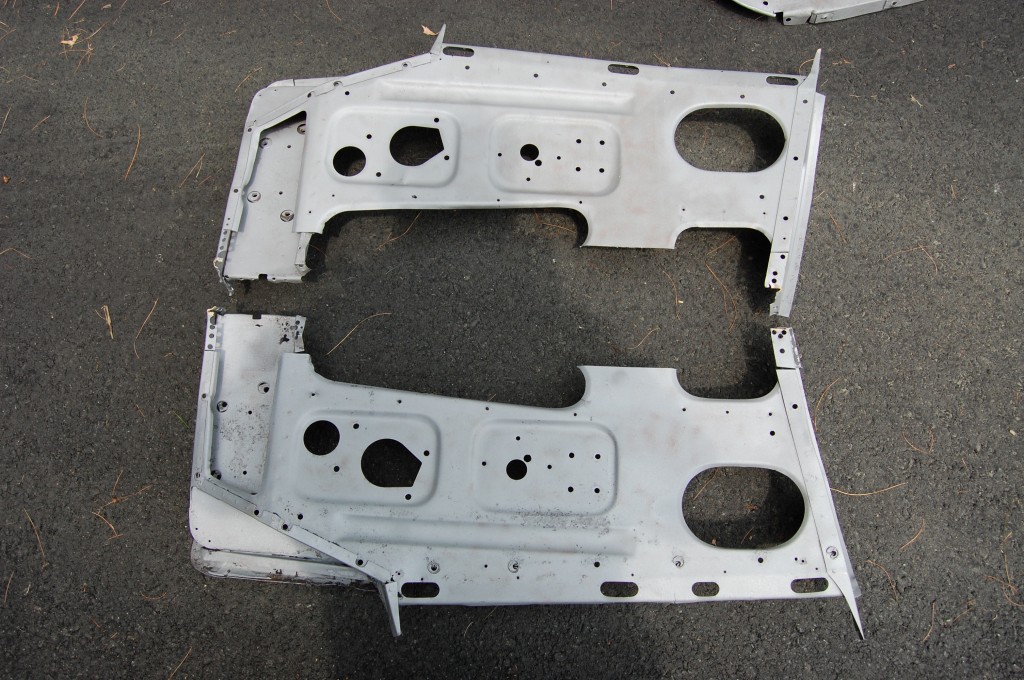

- Another shot of the four doors we will use to build two…

- The early roadster doors had their upper sections spot-welded on.

- We often see rust under this drip tray, but these doors are very bad in this area.

- Here’s the other side – ouch…

- This is the original, factory seam – there’s nothing fancy about that cut!

- White 3.8 shell has no provision for armrest like the black 4.2 shell.

- This 3.8 donor door is in MUCH better shape in this complicated area, and we will use this entire shell for the new RH side door. We will need to remove the drip channel which is the later style and replace it with a new, early style.

- Here are the two shells we are going to attempt to use – note drip channel with small “leg” – that is the later style.

- Shells have been fully dissected now and are ready for blasting.

- Stripping black shipping primer from the reproduction Coupe door skins provided by the customer. We will trim these down just the way they did it at the factory in 1961. Note that it simply takes acetone and a scotch-brite pad to remove this primer (attesting to it’s inferior quality…) – and it’s a real mess…

- These had been sitting around for a while and had rusted under the black shipping primer – proof that you should ALWAYS REMOVE THIS JUNK and start over from fresh, clean metal!

- Door has been stripped without damage and is ready for some REAL primer!

- Re-primed with 2 coats of high quality etch primer.

- Inside of shells BEFORE blasting.

- Inside of shells AFTER blasting.

- Another “post-blasting” shot…

- We started the repairs on the RH door with a small patch TIG-ed into the lower forward corner.

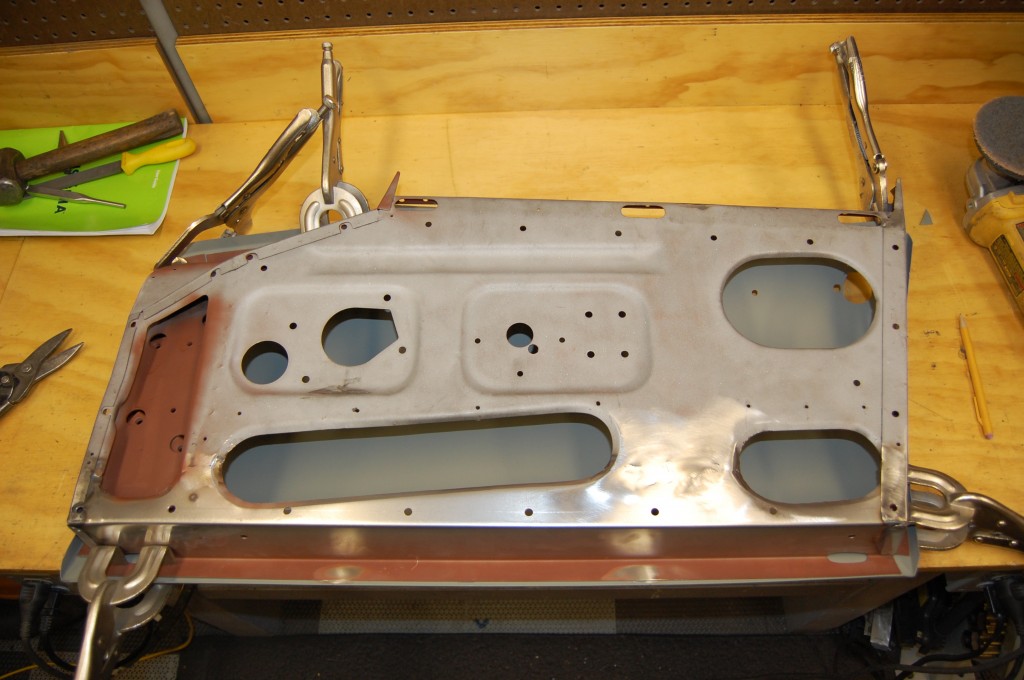

- A new bottom for the door shell has been fabricated and welded in.

- We pick up the inner hinge support in the same locations as original.

- Here is a new, “early style” drip channel fabricated in our shop being fitted.

- This punched hole was a feature of the original, white 1961 doors, the doors on the ’61 roadster in the shop currently, and my own early ’63 roadster – but NOT of the donor, later 3.8 door, so we added it.

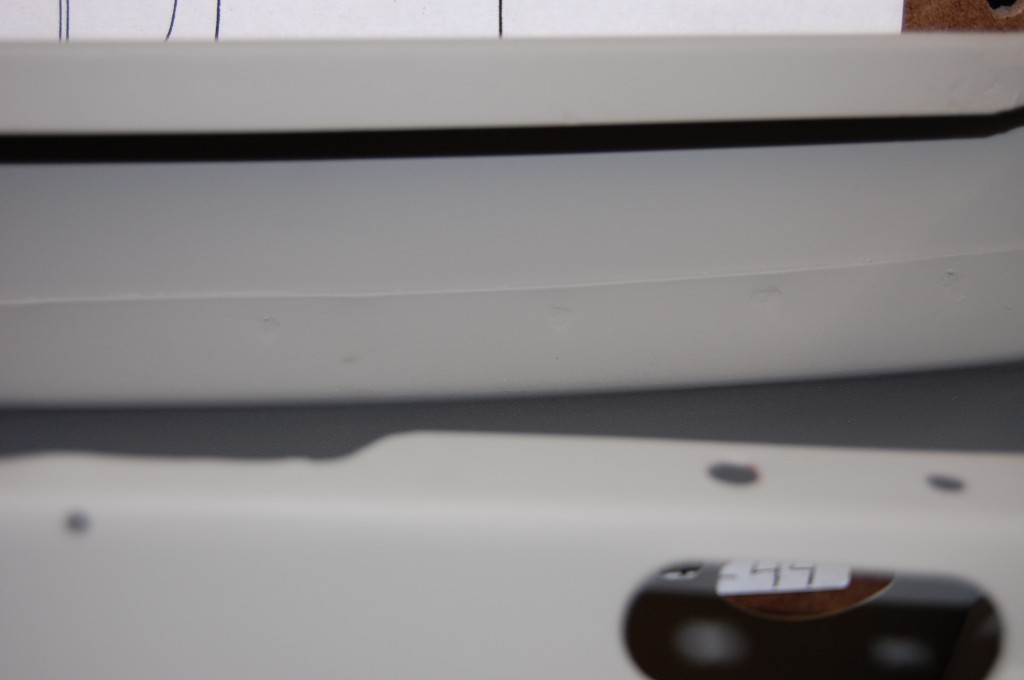

- Showing the later style drip chanel with small “leg” versus the early style without it.

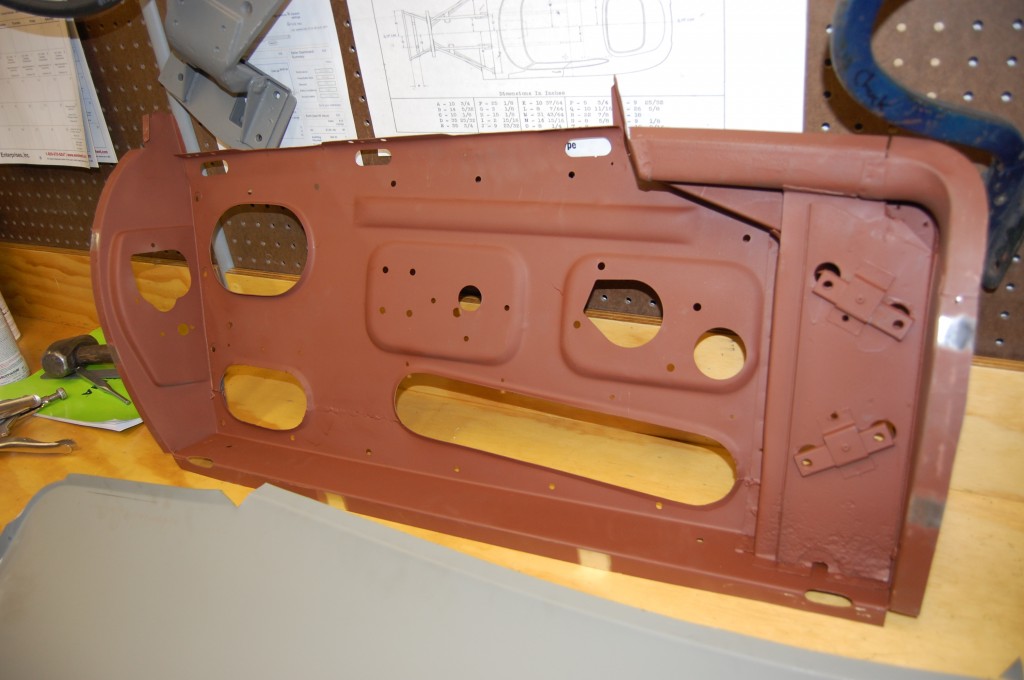

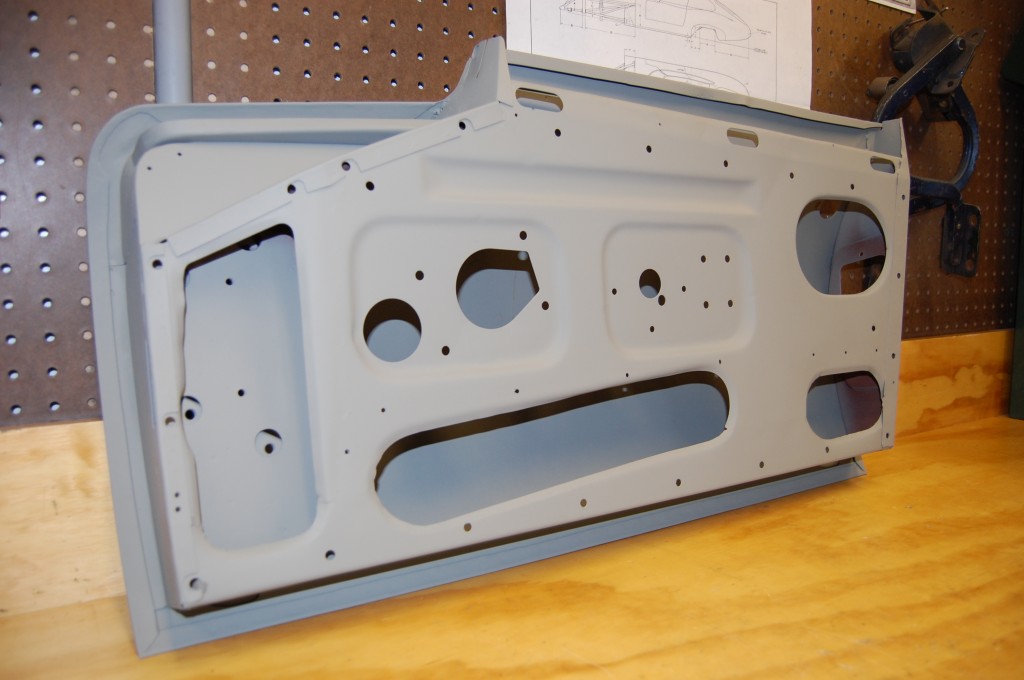

- The completed door shell, coated liberally internally with red oxide primer. This will never rust again.

- The status of the door last night – I’ll add more photos soon. The skin has been fitted and is ready to be spot-welded into place before folding the flange – this is how it was done at the factory – and at Monocoque Metalworks, of course…

- a new drip tray has been formed in our fabrication shop, and has been coated with red oxide on the bottom – the doors originally had no coating between these pieces and it is a common area for rust…

- The new drip tray has been riveted and brazed into place to replicate the original construction exactly.

- Here is the completed passenger door in grey etch primer.

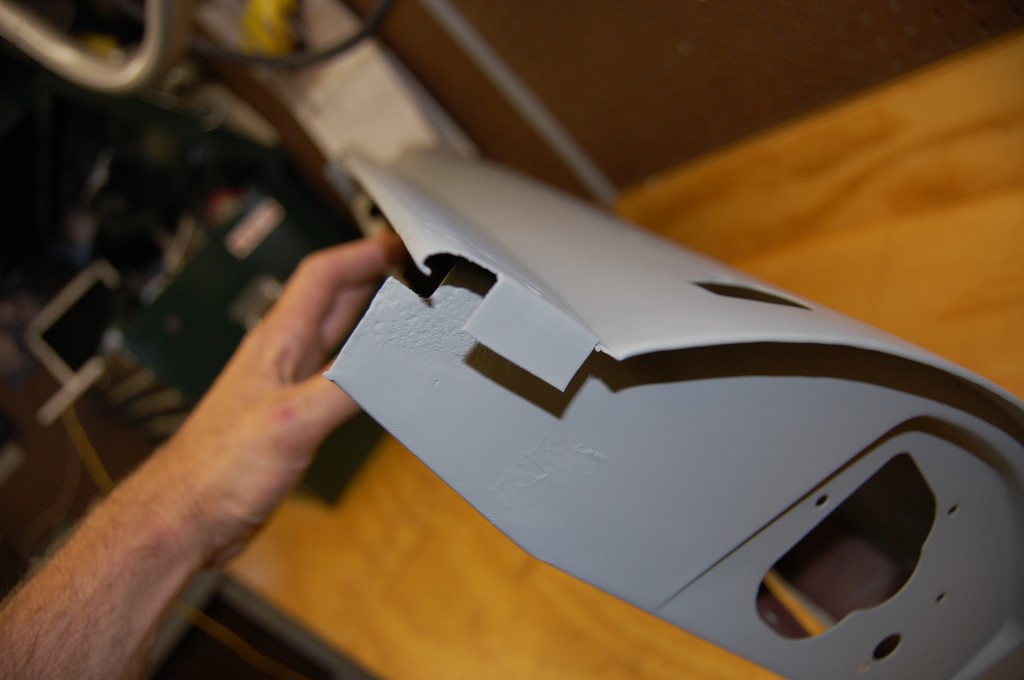

- This little tab is specific to the 1961 roadsters – it was later dropped. The minimal pitting you see here will be handled in the paint phase of the restoiration with some light feather-fill…

- The upper piece has been salvaged from another door skin that was rotted in the bottom section, and spot-welded to the cut-down coupe skin exactly as the originals were in 1961.

- This hole was punched like the early 3.8’s – also note the contoured drain hole about 4 inches up. Later 4.2 doors have a slot instead of the lower hole, and do not have the upper contoured hole at all.

- Here is the backside showing the spot-welds – even from this angle the door is indistinguishable from the original 1961 door.

- The new drip tray does not have the extra “leg” – it is a new piece fabricated in our shop and brazed onto the door as per the originals.